II. Product Performance

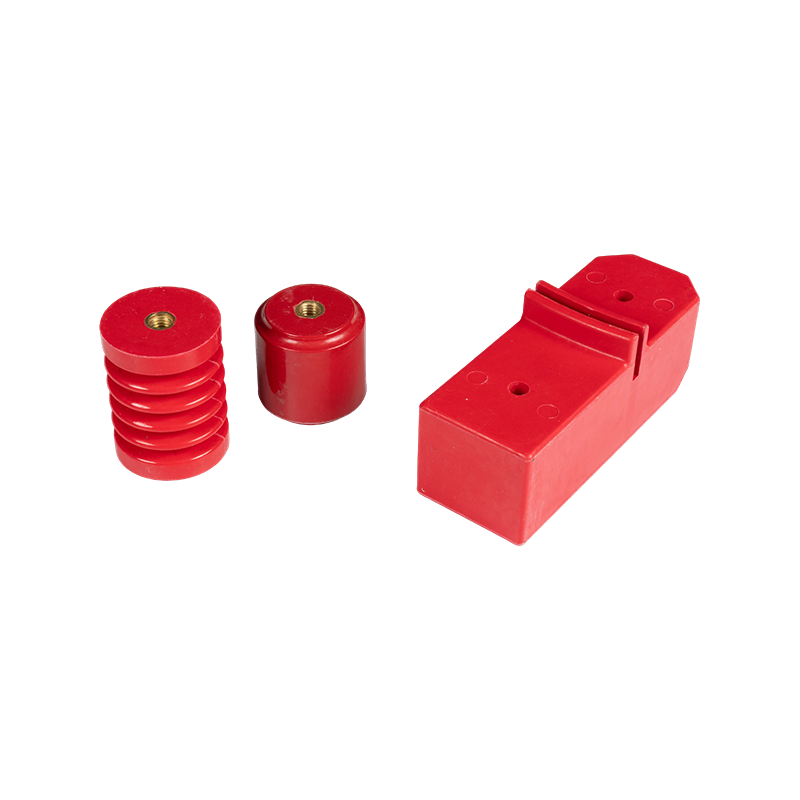

1. Excellent Mechanical Strength: Bending strength and compressive strength are both ≥200MPa, tensile strength can reach up to 900MPa, strong impact resistance (impact strength of unnotched simply supported beam ≥90KJ/m²), capable of stably bearing the weight of the coil and the electrodynamic forces during operation, providing reliable support. 2. Outstanding Insulation and Electrical Performance: Insulation resistance ≥1.0×10¹²Ω under normal conditions, and still ≥1.0×10¹¹Ω after immersion in water for 24 hours; electrical strength in transformer oil at 90℃ ≥10KV/mm, arc resistance ≥180s, tracking resistance ≥600V, effectively isolating coil potential and preventing insulation failure.

3. Good Heat Resistance and Environmental Adaptability: F/H grade temperature resistance standard, long-term operating temperature up to 155℃-180℃, heat distortion temperature ≥240℃, resistant to high-temperature aging; water absorption ≤20mg, moisture-proof and corrosion-resistant, stable performance in humid and complex environments, requiring no additional protection.

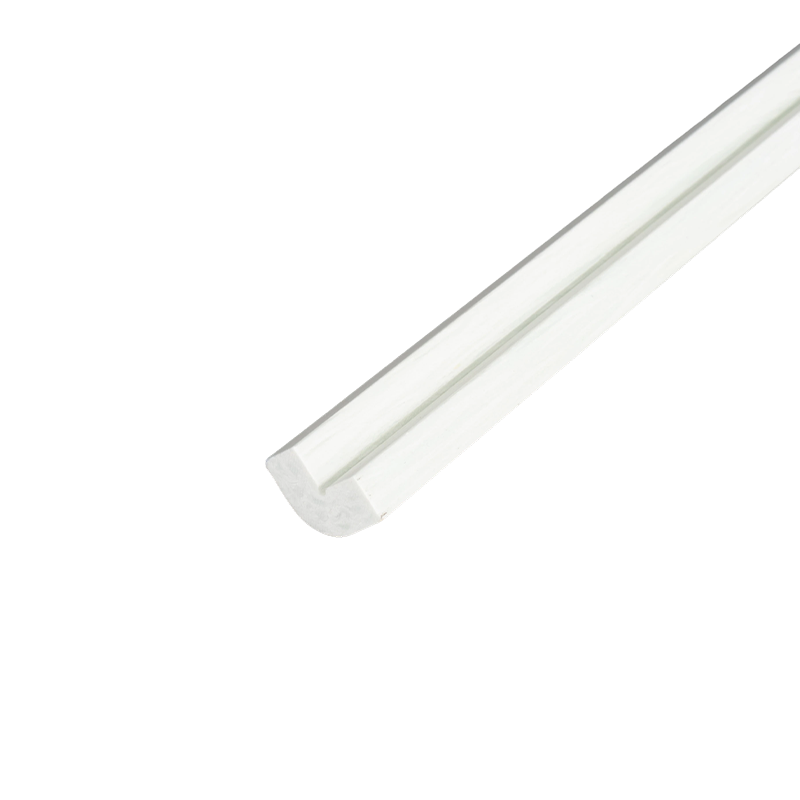

4. Other Advantages: Flame retardancy meets standards, complying with high-voltage electrical safety requirements; smooth surface for easy processing, allowing for quick cutting and assembly, adaptable to automated production processes, and contains no metallic components, thus not affecting the transformer's electromagnetic performance.

III. Product Applications

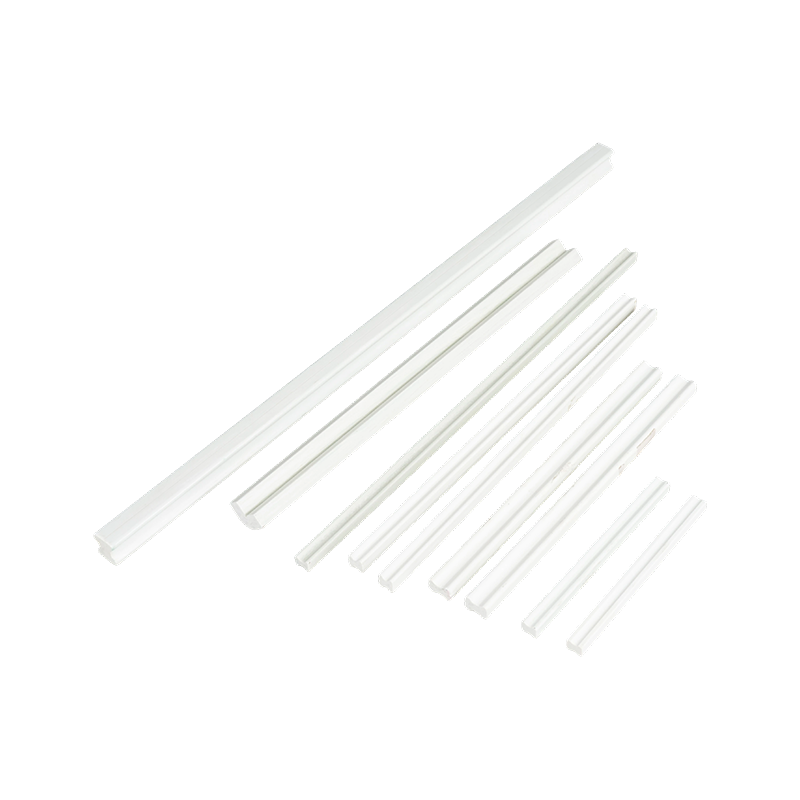

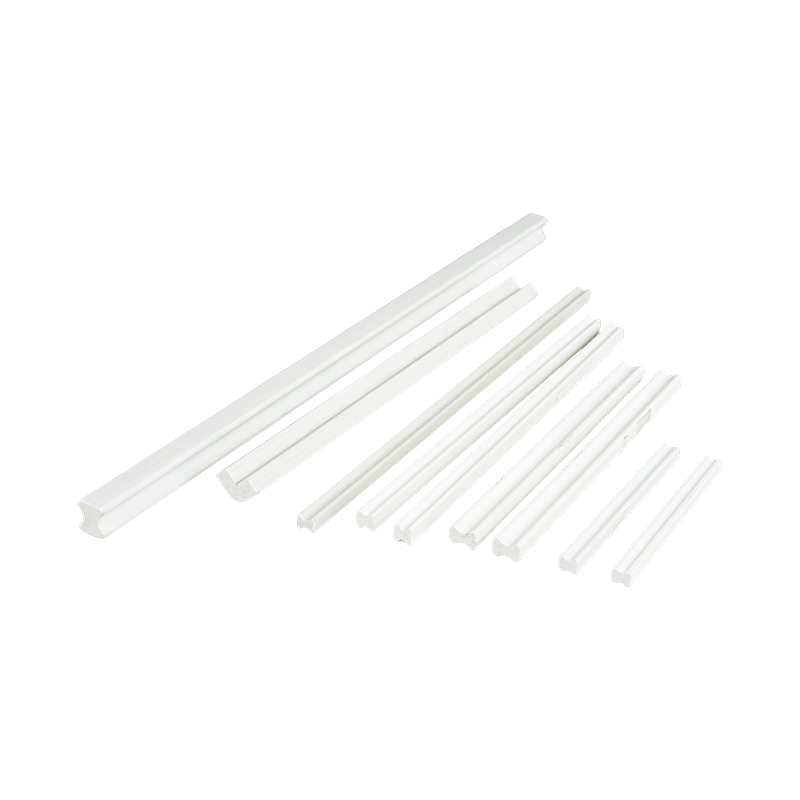

1. Core Application: Coil Interlayer Ventilation and Cooling: Primarily used for interlayer support in dry-type transformer coils. The I-beam structure allows for uniform ventilation gaps, accelerating heat dissipation during transformer operation, reducing coil temperature rise, ensuring long-term stable operation, and preventing overheating damage.

2. Insulation Structure Support: As a core insulation support component inside dry-type transformers, it can be used for spacing support between coils and the core, and between coils and the casing. It is also suitable for internal insulation support in reactors and wave traps, dispersing electric field stress and reducing the risk of partial discharge.

3. Extended Applications: It can also be used as insulation structure components in high-voltage electrical products such as high-voltage frequency converter power modules, power capacitors, disconnect switches, and on-load tap changers, adapting to the insulation and support needs of various high-voltage equipment.

English

English