Product Features:

Electrical Properties: The cured material possesses dielectric strength, volume resistivity, and surface resistivity, preventing current breakdown.

Mechanical Properties: The polyester fiber nonwoven fabric skeleton provides the material with tensile strength and toughness, allowing it to maintain its structure during punching, bending, and assembly.

Heat Resistance: The epoxy resin system enables it to operate at 155°C (Class F) or higher, exhibiting stable thermal properties and low thermal shrinkage.

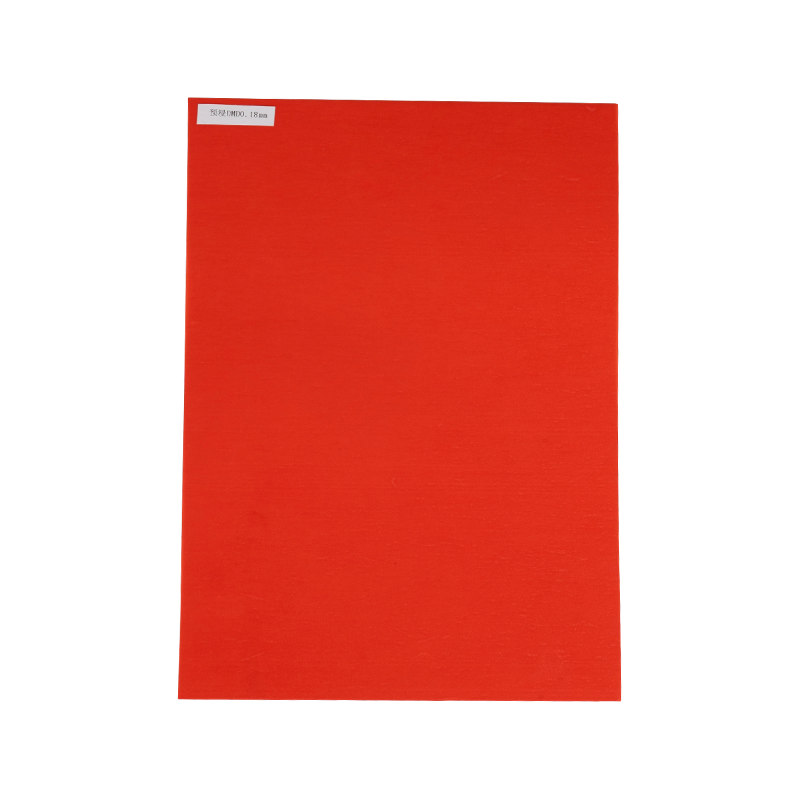

Processability: At room temperature, it is a dry sheet that can be cut and placed. Under heat and pressure, the epoxy resin melts, flows, and cures, filling irregular surfaces and bonding with the insulated material to form an insulating layer.

Chemical Resistance and Moisture Resistance: The cured insulation layer resists moisture, grease, and various chemical solvents.

Main Applications:

DMD Epoxy Prepreg is used for insulation treatment of various motors (such as high-voltage motors and traction motors), transformers, instrument transformers, electrical coils, and other electrical equipment. Typical applications include: Slot Insulation: Used in the stator or rotor core slots of motors to isolate the coils from the core.

Phase Insulation: Used to isolate windings of different phases in a motor.

Pad insulation: Used as padding for insulation between coil ends or to ground.

Interlayer insulation: Used for insulation separation between transformer winding layers or other applications requiring insulation separation.

| Serial number | Property | Unit | Requirement | |||||

| 1 | Nominal thickness | mm | 0.15 | 0.18 | 0.2 | 0.25 | 0.3 | 0.4 |

| 2 | Allowable thickness deviation | mm | ±0.02 | ±0.03 | ±0.04 | |||

| 3 | Tensile strength (longitudinal, no bending) | N/10mm | ≥70 | ≥80 | ≥100 | |||

| 4 | Soluble resin content | g/m² | ≥45 | ≥45 | ≥45 | |||

| 5 | Volatile content | % | ≤1.5 | ≤1.5 | ≤1.5 | |||

| 6 | Breakdown voltage | kV | ≥7.0 | ≥8.0 | ≥10 | |||

| 7 | Tensile shear strength | Mpa | ≥3.0 | ≥3.0 | ≥3.0 | |||

| 8 | Temperature index | ≥155 | ≥155 | ≥155 | ||||

English

English