Features:

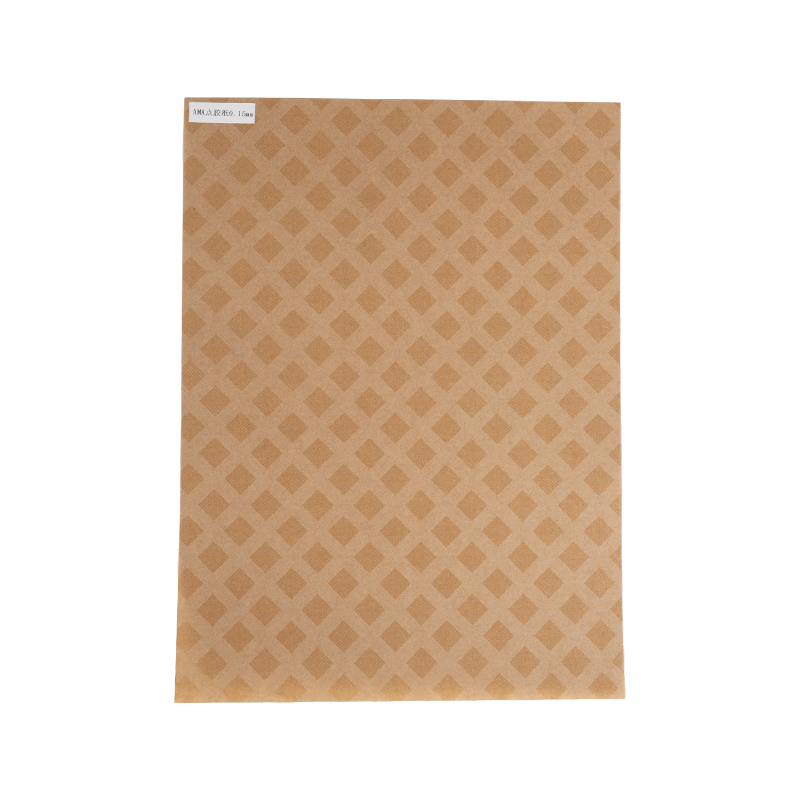

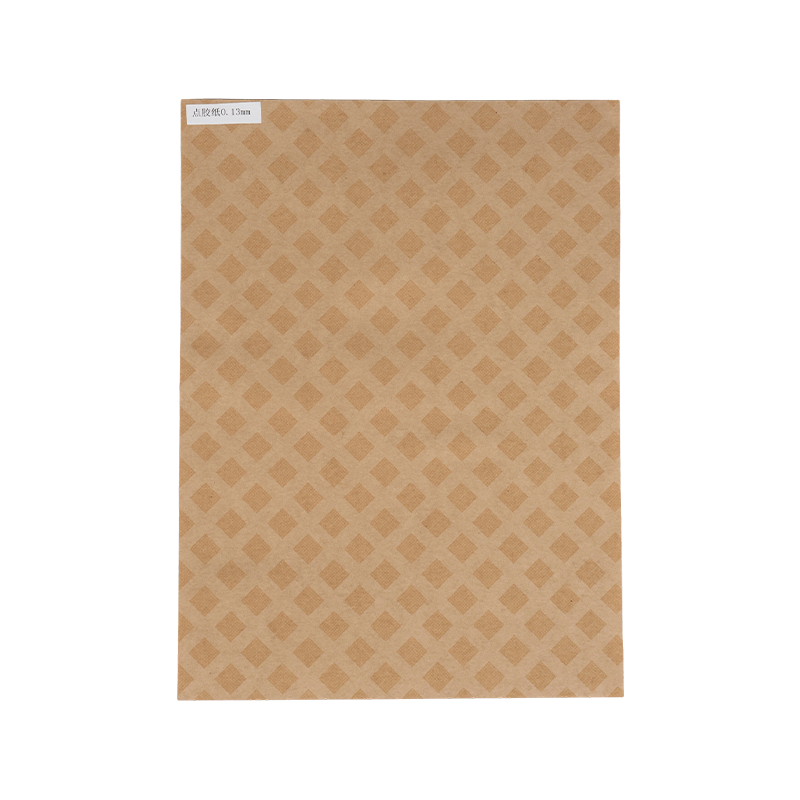

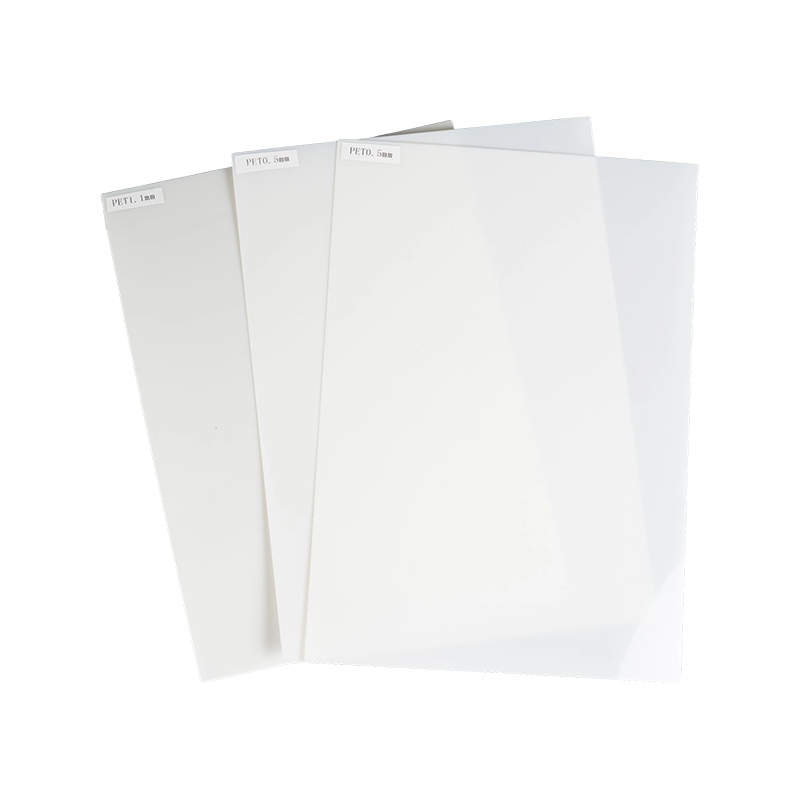

Structure and Process: This product typically uses high-performance cellulose insulating paper as the matrix, its surface coated with an epoxy resin system of a specific chemical composition using specialized equipment, forming regular, discontinuous diamond or dotted patterns.

Adhesion Mechanism: During the drying and curing process after coil manufacturing, DDP is heated to the activation temperature of the epoxy resin, causing the resin dots to melt and flow. Under continuous heating, the resin undergoes a cross-linking reaction and cures, firmly bonding adjacent conductors, foil layers, or insulating materials together.

Mechanical Properties: After the resin cures, it forms an adhesive between the layers of the transformer coil, thereby improving the overall structural integrity of the coil. This helps limit the displacement of the winding under electromagnetic forces.

Electrical and Oil Impregnation Properties: Its dotted structure ensures that most areas of the insulating paper remain open, facilitating the penetration and flow of transformer oil. This characteristic is beneficial for establishing the dielectric strength of the insulation system and dissipating heat.

Typical Application Scenarios:

* Power Transformers: Used as interlayer and inter-turn insulation material in oil-immersed transformers to ensure the stability of the insulation system under high temperature and high pressure environments.

* Special Electrical Equipment: Suitable for transformers, reactors, and other electrical equipment requiring a paint-free process, improving heat dissipation efficiency and reducing processing steps.

| Property | Unit | Values | |||||

| Thickness of base paper | mm | 0.08±0.005 | 0.13±0.007 | 0.18±0.01 | 0.20±0.01 | 0.25±0.01 | |

| Density of base paper | g/m³ | 0.85-1.1 | 0.85-1.1 | 0.85-1.1 | 0.85-1.1 | 0.85-1.1 | |

| One-sided adhesive thickness | u m | 10-15 | 10-15 | 10-15 | 10-15 | 10-15 | |

| Moisture | % | 4.0-8.0 | 4.0-8.0 | 4.0-8.0 | 4.0-8.0 | 4.0-8.0 | |

| Welding strength | Room temperature | 650 | 650 | 650 | 650 | 650 | |

| 100℃±2℃ | 400 | 400 | 400 | 400 | 400 | ||

| Oil absorption | %≥ | 200 | 200 | 200 | 200 | 200 | |

| For the pollution of transformer oil |

Free from contamination(tan8<0.001) | ||||||

| Tensile strength |

MD | N/10m mwidth ≥ |

60 | 110 | 160 | 1 80 | 230 |

| CMD | 30 | 50 | 70 | 80 | 1 00 | ||

| Tensile strength |

MD | mN≥ | 450 | 900 | 1350 | 1 500 | 2000 |

| CMD | 500 | 1 000 | 1500 | 1 700 | 2300 | ||

| Breakdown Voltage |

In air | Kv≥ | 0.88 | 1.37 | 2 | 2.1 | 2.25 |

| In oil | 4.4 | 7 | 9 | 9.8 | 11.5 | ||

English

English