Technical Features:

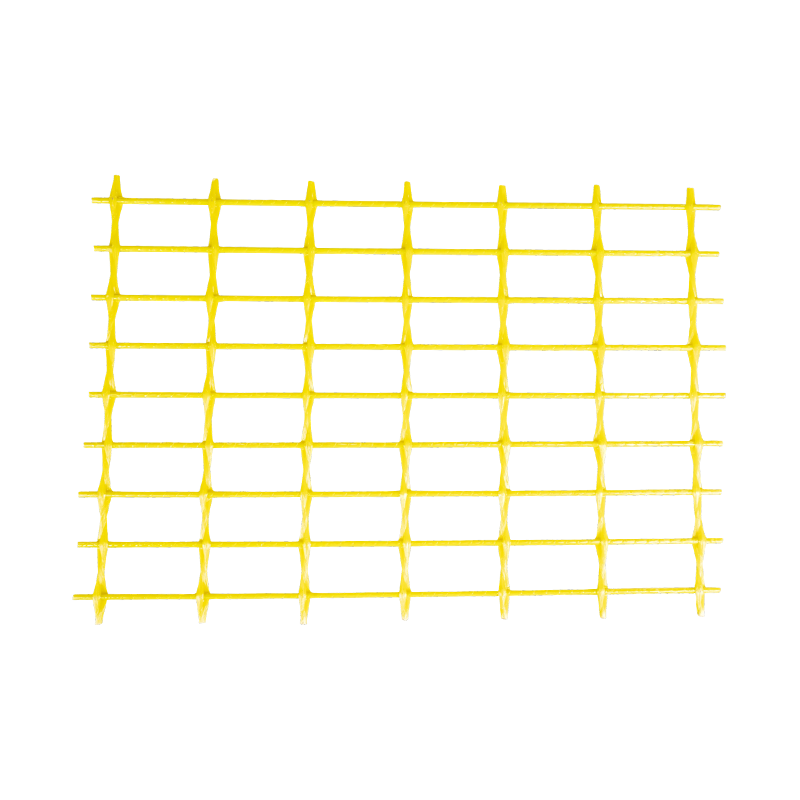

Alkali Resistance: The mesh fabric treated with a special alkali-resistant coating retains ≥50% of its alkali-resistant tensile strength after immersion in saturated cement filtrate for 28 days, maintaining stable performance in alkaline environments with a pH of 12-14.

Mechanical Strength: The tensile strength (warp and weft) of this product reaches over 1350 N/5cm (standard type) to over 2200 N/5cm (reinforced type), more than three times the tensile strength of ordinary silicate cement mortar.

Durability: The product maintains stable performance after 100 freeze-thaw cycles, with a temperature resistance range of -50℃ to 150℃, adapting to various climatic conditions.

Dimensional Stability: Elongation at break is controlled at ≤5% (warp and weft), effectively dispersing stress.

Construction precautions:

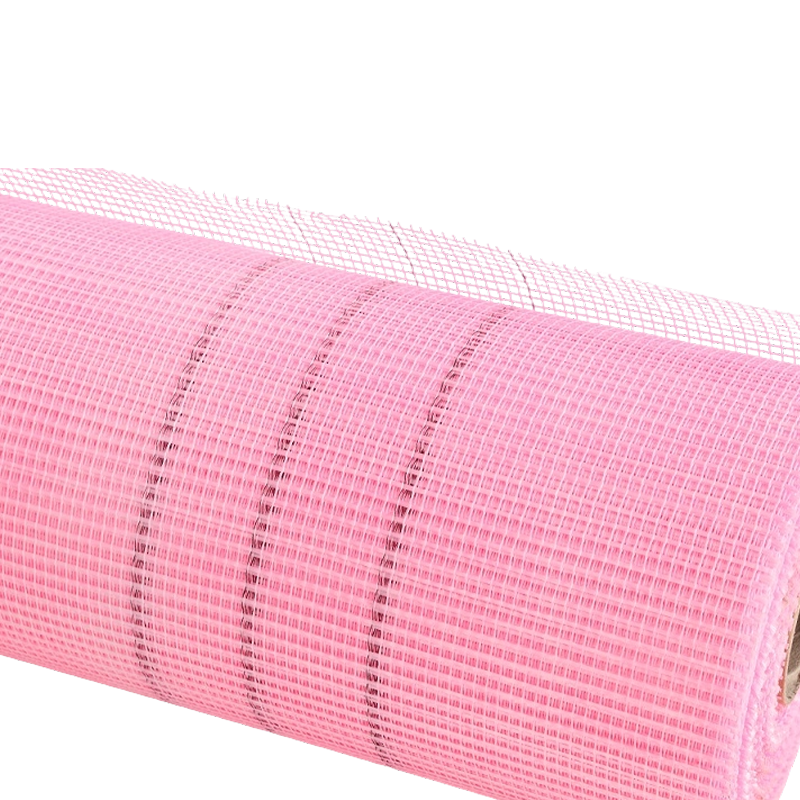

When using 130-160g exterior wall fiberglass mesh fabric, the following construction methods must be followed: The overlap width between mesh fabrics should be no less than 50mm, with an overlap width of ≥50mm at internal corners and ≥200mm at external corners.

During construction, the mesh fabric should be laid flat and wrinkle-free, with mortar fullness reaching 100%. A "two-coat finishing method" should be used to ensure the mesh fabric is completely covered.

The mesh fabric should be located at the outer 1/3 of the entire protective layer thickness to ensure optimal performance.

Applications:

External Wall Insulation System (ETICS): Used in combination with insulation materials such as EPS, XPS, and rock wool boards to enhance impact resistance and prevent cracking of the insulation layer.

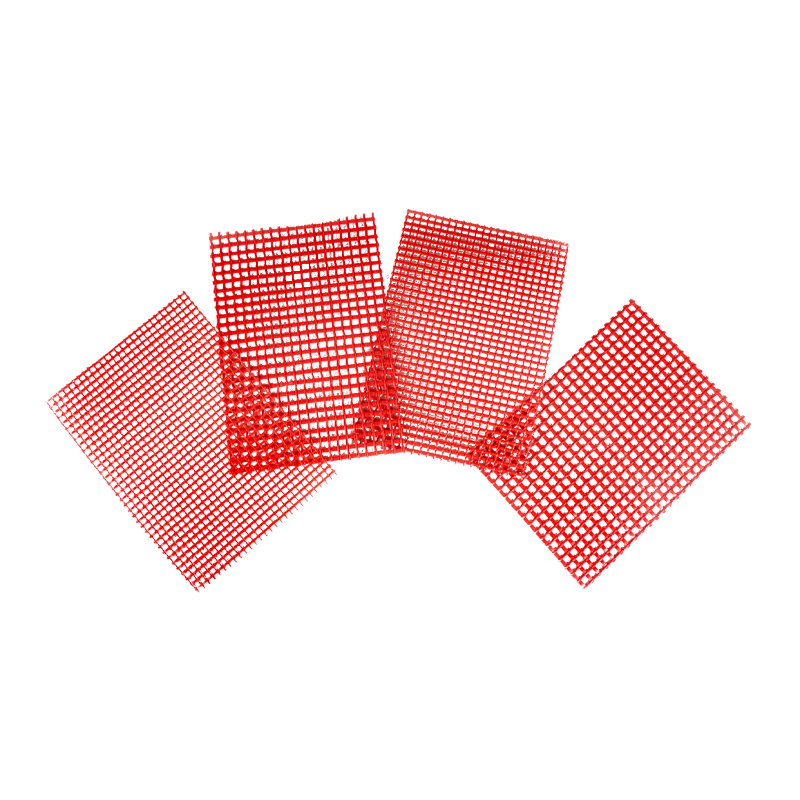

High-strength requirements: For areas prone to cracking, such as the exterior walls of high-rise buildings, internal and external corners, and door and window openings, 4mm×4mm mesh fabric is commonly used for reinforcement.

Special environment buildings: For exterior walls in harsh environments such as coastal high-salt and alkaline areas and chemical industrial parks, reinforced mesh fabrics with a density of 160g/m² or higher offer better corrosion resistance, ensuring the durability of the insulation system.

Tile veneer substrate: Serves as a crack-resistant substrate, reducing the risk of tile detachment and hollowing.

| No. of Product | Width (mm) | Model of Raw Yam (tex) | Model of Raw Yam (tex) | Mesh (mm) | Mesh (mm) | Mesh (mesh/inch) | Mesh (mesh/inch) | Weave | Resin Content (%) | Weight (g/m 2) | Fracture Strength (N/50mm) | Fracture Strength (N/50mm) |

| Warp | Woof | Warp | Woof | Warp | Woof | Warp | Woof | |||||

| 1 | 1000-1250 | 32x2 | 204 | 5 | 5 | 5 ± 0.5 | 5 ± 0.5 | union | 20 ± 2 | 65 ± 3 | 500 | 500 |

| 2 | 1000-1250 | 50x2 | 255 | 5 | 5 | 5 ± 0.5 | 5 ± 0.5 | union | 18 ± 2 | 80 ± 3 | 800 | 900 |

| 3 | 1000-1250 | 100x2 | 306 | 5 | 5 | 5 ± 0.5 | 5 ± 0.5 | union | 18 ± 2 | 125 ± 3 | 1100 | 1300 |

| 4 | 1000-1250 | 134x2 | 357 | 5 | 5 | 5 ± 0.5 | 5 ± 0.5 | union | 18 ± 2 | 145 ± 3 | 1300 | 1500 |

| 5 | 1000-1250 | 134x2 | 408 | 5 | 5 | 5 ± 0.5 | 5 ± 0.5 | union | 18 ± 2 | 2160 ± 3 | 1500 | 1700 |

| 6 | 1000-1250 | 50x2 | 204 | 4 | 5 | 6 ± 0.5 | 5 ± 0.5 | union | 18 ± 2 | 80 ± 3 | 550 | 800 |

| 7 | 1000-1250 | 100x2 | 255 | 4 | 5 | 6 ± 0.5 | 5 ± 0.5 | union | 18 ± 2 | 110 ± 3 | 1100 | 1000 |

| 8 | 1000-1250 | 134x2 | 306 | 4 | 5 | 6 ± 0.5 | 5 ± 0.5 | union | 18 ± 2 | 150 ± 3 | 1400 | 1500 |

| 9 | 1000-1250 | 32x2 | 204 | 4 | 4 | 6 ± 0.5 | 6 ± 0.5 | union | 19 ± 2 | 80 ± 3 | 550 | 850 |

| 10 | 1000-1250 | 100x2 | 204 | 4 | 4 | 6 ± 0.5 | 6 ± 0.5 | union | 18 ± 2 | 120 ± 3 | 1100 | 900 |

| 11 | 1000-1250 | 134x2 | 255 | 4 | 4 | 6 ± 0.5 | 6 ± 0.5 | union | 18 ± 2 | 150 ± 3 | 1500 | 1600 |

| 12 | 1000-1250 | 134x2 | 306 | 4 | 4 | 6 ± 0.5 | 6 ± 0.5 | union | 18 ± 2 | 160 ± 3 | 1500 | 1800 |

| 13 | 1000-1250 | 50x2 | 306 | 5 | 6 | 5 ± 0.5 | 4 ± 0.5 | union | 18 ± 2 | 80 ± 3 | 500 | 1000 |

| 14 | 1000-1250 | 100x2 | 357 | 5 | 6 | 5 ± 0.5 | 4 ± 0.5 | union | 18 ± 2 | 110 ± 3 | 1000 | 1200 |

| 15 | 1000-1250 | 255x2 | 408 | 10 | 10 | 2.5 | 2.5 | union | 18 ± 2 | 220 ± 3 | 1000 | 1200 |

| 16 | 1000-1250 | 255x2 | 561 | 10 | 10 | 2.5 | 2.5 | union | 18 ± 2 | 125 ± 3 | 1000 | 1400 |

| 17 | 1000-1250 | 375x2 | 561 | 10 | 10 | 2.5 | 2.5 | union | 18 ± 2 | 145 ± 3 | 1400 | 1500 |

| 18 | 1000-1250 | 375x2 | 561 | 10 | 10 | 2.5 | 2.5 | union | 18 ± 2 | 160 ± 3 | 1500 | 1600 |

| 19 | 1000-1250 | 33x2 | 67 | 2.8 | 2.8 | 9 ± 0.5 | 9 ± 0.5 | union | 21 ± 2 | 45 ± 3 | 600 | 600 |

English

English