I. Core Product Performance

1. Electrical Insulation Performance

High Breakdown Strength: Power frequency breakdown strength ≥20kV/mm, able to withstand high voltage surges, effectively isolating transformer windings, busbars, and other energized components from grounding structures, preventing short-circuit faults, and meeting the insulation requirements of medium and high voltage transformers.

Stable Insulation Resistance: Volume resistivity ≥10¹⁴Ω·m, stable surface resistivity, minimal performance degradation under high temperature and high humidity environments, no risk of increased leakage current, ensuring long-term insulation reliability of equipment.

Low Dielectric Loss + Corona Resistance: Low energy loss under high-frequency electric fields, reducing equipment operating heat generation and delaying insulation aging; excellent corona resistance, resisting electrical erosion caused by partial discharge, extending service life.

Flame Retardancy Compliance: Meets UL94 V-0 flame retardant standards, self-extinguishing upon contact with open flame, effectively preventing the spread of transformer fires and improving equipment safety.

2. Physical and Mechanical Properties

Excellent Mechanical Strength: High tensile and compressive strength, strong bending resistance, suitable as a support component to withstand winding weight, winding stress, and operating vibration without deformation or breakage risk.

Good Dimensional Stability: Dense structure and low shrinkage after curing; no significant shrinkage/expansion with temperature fluctuations or humidity changes, maintaining fit with transformer components and ensuring stable insulation gaps.

Flexible Machinability: Can be drilled, milled, and cut; can be customized with complex shapes and strict dimensional tolerances, adapting to diverse needs such as coil frames and insulating partitions.

3. Environmental and Chemical Resistance

Strong Heat Resistance: Heat resistance rating covers Class B (130℃) to Class H (180℃), able to withstand the high operating temperatures of transformers; physical and chemical properties do not deteriorate under long-term high-temperature conditions, and there is no softening or deformation.

Moisture and Corrosion Resistant: Extremely low water absorption rate; insulation and mechanical properties remain unchanged even in humid environments; withstands transformer oil, common acid and alkali mists, and oil contamination without swelling or cracking, suitable for complex environments such as humid and chemical zones.

Transformer Oil Compatibility: Stable performance even after long-term immersion in transformer oil; no components leach, does not affect the insulation effect of the transformer oil, suitable for use inside oil-immersed transformers.

II. Product Applications

1. Transformer Internal Structural Insulation

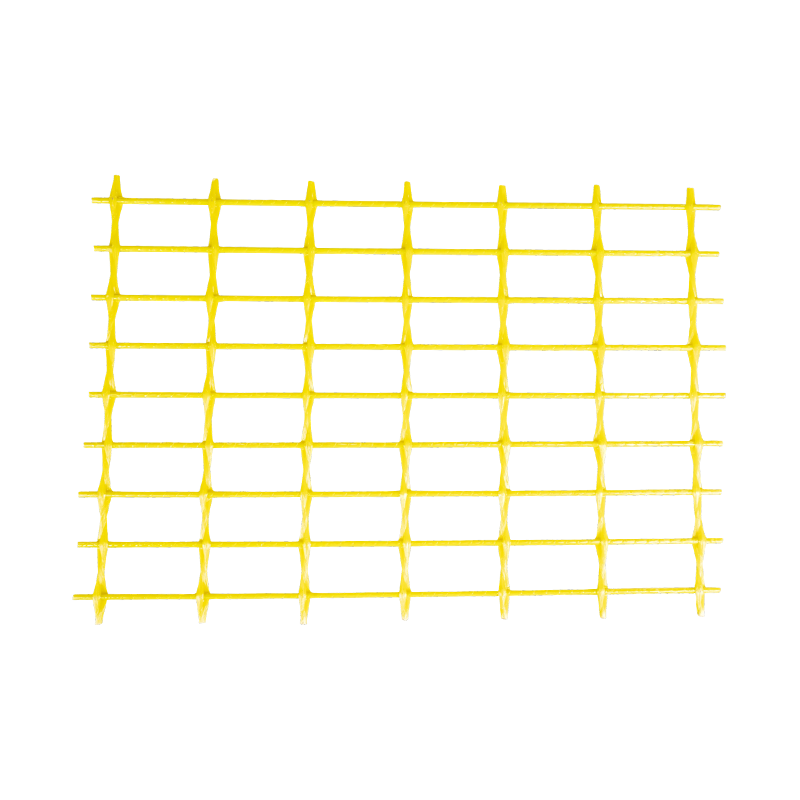

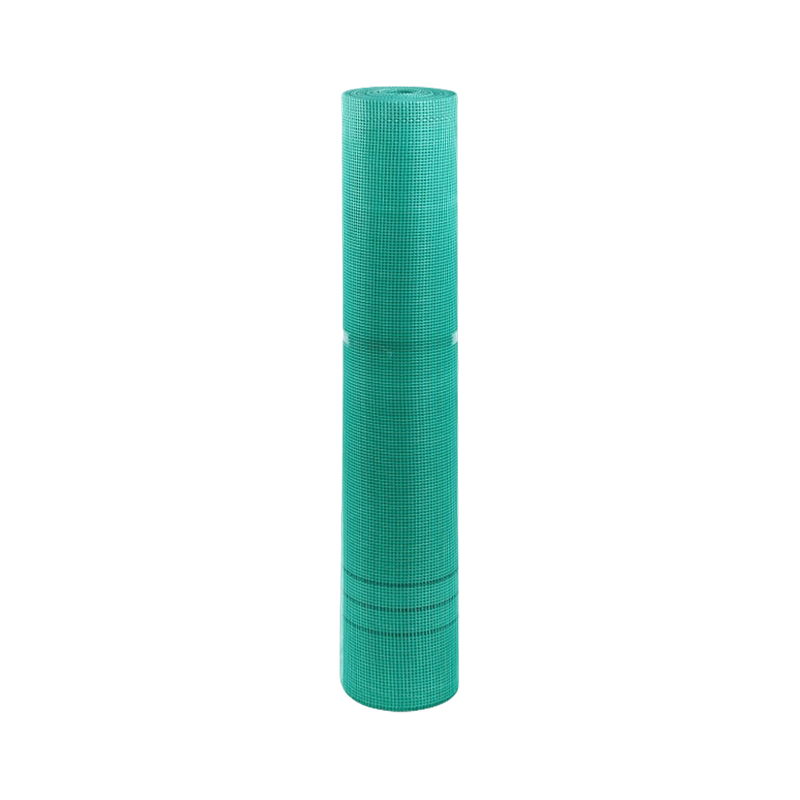

Winding Interlayer/Phase Interlayer Insulation: Cut into thin sheets (0.3~3mm thick) and placed between coil layers or between different phase windings, providing reliable electrical isolation and preventing inter-winding discharge; a core component of medium and high voltage transformer winding insulation.

Structural Component Isolation Pad: Placed between the core clamp and the tank, and between the winding pressure plate and the clamp (2~5mm thick), filling gaps between components, ensuring potential difference isolation, and avoiding the risk of partial discharge.

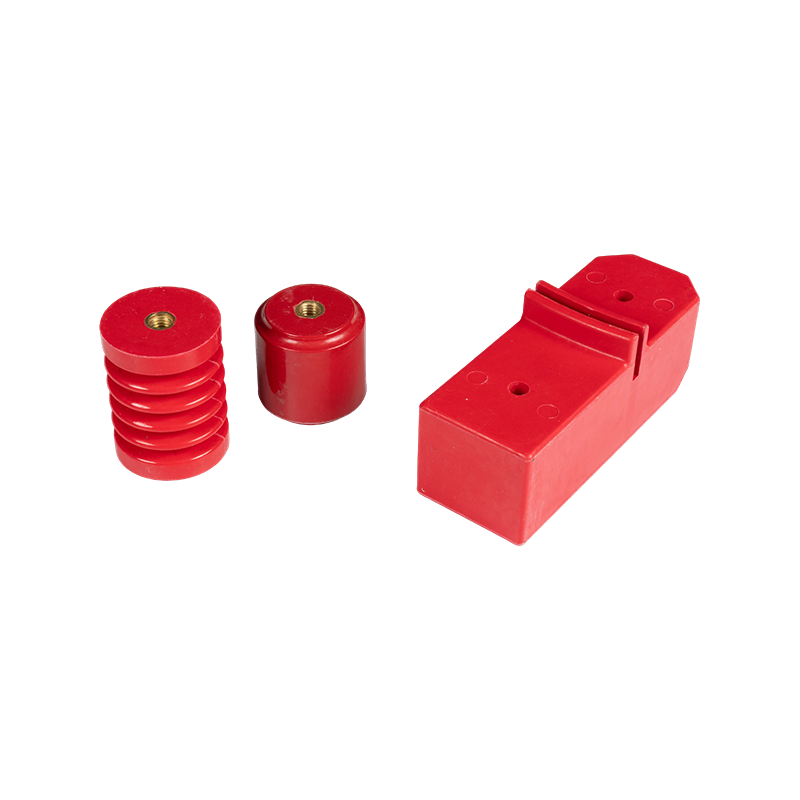

2. Component Support and Fixing

Coil Frame/Support: Fabricated as a frame structure (3~20mm thick), it supports the transformer windings, fixes the coil position, prevents winding displacement and deformation during operation or transportation, and ensures the stability of the winding structure.

Busbar/Leader Support Insulation Plate: Installed between the busbar, leads, and transformer housing (2~10mm thick), it fixes conductive components and provides insulation to prevent partial discharge. It is compatible with various transformer outgoing line systems.

3. Sealing and Insulation Scenarios

Flange Sealing Insulation Gasket: Used at the connection points of transformer tank flanges and bushing junction boxes. Utilizing its flatness and adaptability, it fills minor unevenness on the sealing surface after compression, providing both insulation and sealing functions to prevent transformer oil leakage and moisture intrusion.

Internal Gap Sealing: Fills minor gaps in the transformer's internal structure, ensuring insulation and improving the overall structural sealing. Suitable for use in the oil-immersed transformer's hydraulic environment.

4. Specialized Transformer Applications

Dry-type Transformers: Utilizing high flame-retardant epoxy insulation pads for winding support and bottom insulation, suitable for dry-type transformers in densely populated areas such as buildings and subways, balancing insulation and fire protection requirements.

High-Temperature/Humid Environment Transformers: Transformers in chemical and seafood processing areas use high-heat-resistant and moisture-resistant epoxy insulation pads to withstand high-temperature and high-humidity environments, preventing insulation failure.

Ultra-High Voltage Transformers: Employing H-class heat-resistant epoxy insulation pads for internal core structural support and insulation, resistant to strong electric fields and high temperatures, ensuring stable equipment operation.

English

English