I. Core Product Performance

1. Electrical Insulation Performance

High Breakdown Strength: Porcelain insulators have a breakdown strength ≥35kV/mm, and composite insulator core rods have a breakdown strength ≥20kV/mm. They can withstand power frequency voltage, switching overvoltage, and lightning overvoltage impulses, preventing surface flashover or breakdown.

Excellent flashover resistance: The silicone rubber sheds of the composite insulator are hydrophobic (hydrophobic migration ≥ level 3), and the surface of the porcelain insulator can be coated with an anti-flashover coating. In humid, dusty, and salt spray environments, the surface leakage current is low, and the flashover voltage is 30%~50% higher than that of ordinary porcelain insulators.

Low dielectric loss: The dielectric loss tangent tanδ ≤ 0.002 (power frequency) results in low heat generation during operation, no risk of partial discharge, and suitability for the harsh electric field environment of UHV transformers.

Stable insulation resistance: The volume resistivity is ≥ 10¹⁴ Ω·m, and the insulation performance shows no significant degradation during long-term operation, meeting the design life requirement of transformers exceeding 20 years.

2. Mechanical Properties

High Mechanical Strength: Porcelain insulators withstand bending failure loads ≥8kN (10kV class) and ≥120kN (1000kV class); composite insulators withstand tensile failure loads ≥70kN. They can withstand conductor weight, wind loads, seismic loads, and transformer operating vibrations without risk of breakage or deformation.

Good Fatigue Resistance: After 10⁶ mechanical fatigue cycles, the strength retention rate is ≥90%, withstanding electromagnetic vibrations and environmental stress changes during transformer operation.

Reliable Sealing Performance: Bushing insulators utilize a metal-ceramic/glass sealing process, with a sealing air pressure leakage rate ≤1×10⁻⁹Pa·m³/s, preventing moisture and impurities from entering the interior and avoiding moisture absorption of the insulating oil or aging of the core rod.

3. Environmental and Heat Resistance Performance

Strong Weather Resistance: Porcelain/glass insulators withstand temperatures from -60℃ to 150℃, while composite insulators withstand temperatures from -50℃ to 180℃, adapting to harsh outdoor environments such as extreme cold, extreme heat, and UV radiation without cracking, aging, or fading.

Corrosion Resistance: Porcelain insulators are resistant to acid, alkali, and salt spray corrosion (no damage after 1000 hours of salt spray testing). Composite insulators with silicone rubber sheds are resistant to ozone and UV aging, making them suitable for corrosive environments such as coastal areas and chemical industrial zones.

Heat Resistance Rating Matching: The heat resistance rating is consistent with the transformer body (Class A to Class H). Internal insulators near the windings can withstand temperatures above 130℃ without thermal deformation or insulation degradation.

4. Anti-Aging and Explosion-Proof Performance

Anti-Aging Capacity: Composite insulator core rods are made of acid-resistant epoxy resin, and UV stabilizers are added to the sheds, resulting in a service life of ≥30 years. Porcelain insulators exhibit no aging issues and maintain stable long-term performance.

Explosion-proof Safety: Glass insulators will spontaneously explode when struck by lightning or undergo a breakdown, facilitating timely fault detection; composite insulators do not produce flying fragments after breakdown, avoiding secondary damage, making them suitable for transformers in densely populated areas.

II. Product Applications

Bushing Insulators (Core Application)

The core insulating component of transformer outgoing bushings, divided into porcelain bushings and composite bushing insulators. Installed on the transformer tank cover, one end connects to the internal winding leads, and the other end connects to the external busbar, achieving insulation isolation between the energized leads and the grounding tank, while also supporting the load of the external busbar.

10kV~35kV transformers mostly use porcelain bushing insulators, while 110kV and above transformers often use composite bushing insulators (lightweight and resistant to pollution flashover). UHV transformers use capacitive bushing insulators (with built-in capacitor cores to optimize electric field distribution).

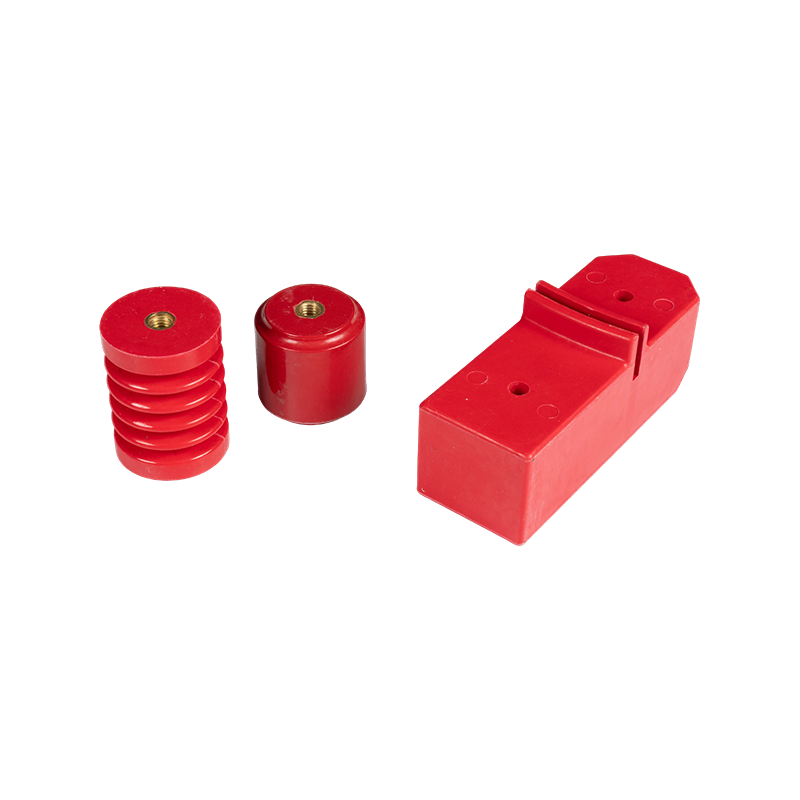

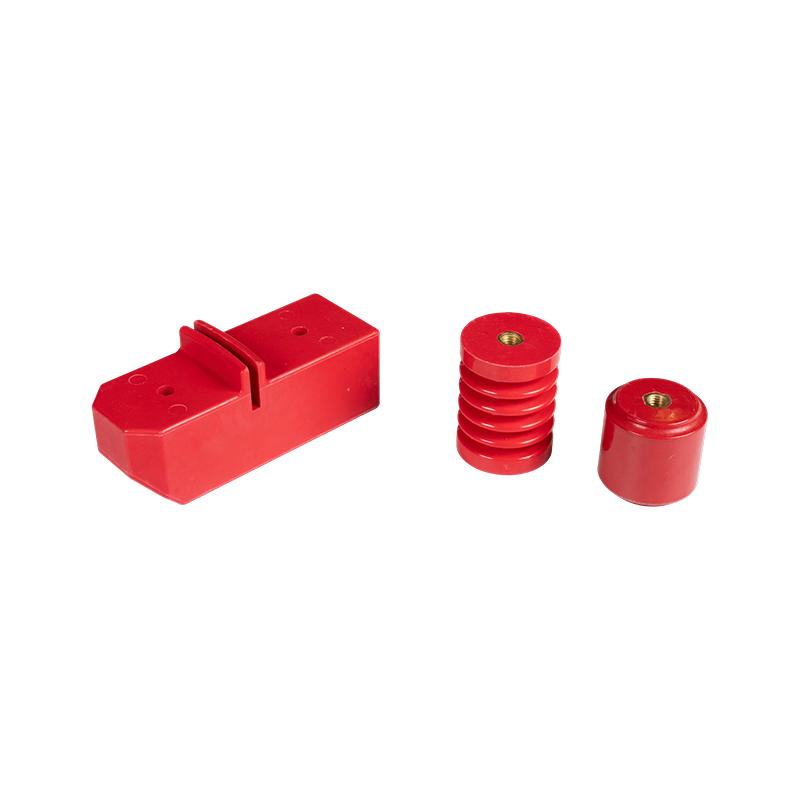

2. Internal Support Insulators

Tap Changer Insulators: Installed inside the on-load tap changer, supporting the contacts and terminals, isolating live parts of different tap positions, and preventing short circuits during tap switching. Suitable for oil-immersed/dry-type tap changers.

Winding Outgoing Line Insulators: Secure the high-voltage leads inside the transformer, ensuring the insulation distance between the leads and the core/clamps, preventing discharge caused by lead swaying. Commonly found in large-capacity power transformers.

Core Grounding Insulators: Used in single-point core grounding circuits, isolating the core from the grounding box, monitoring the core grounding current, and preventing multi-point core grounding faults. A key component for transformer safety protection.

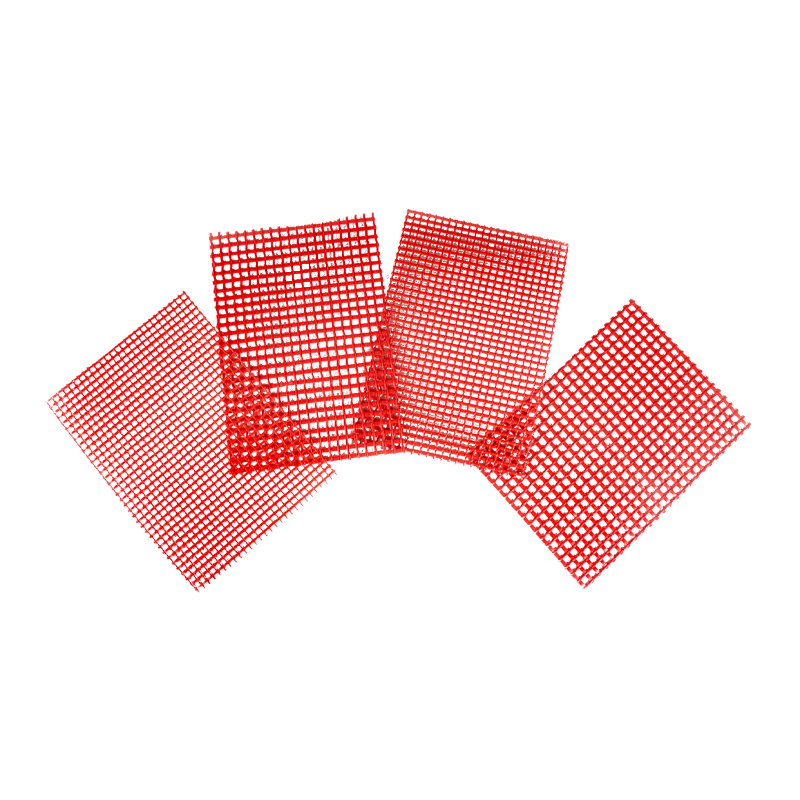

3. External Busbar Insulators

Installed on the busbar supports outside the transformer body, supporting the high-voltage busbar, isolating the busbar from the grounding support/wall, ensuring the insulation distance between the busbar and ground, and suitable for transformer outgoing busbar systems in outdoor substations.

Composite insulators are preferred for outdoor applications (resistant to pollution flashover and lightweight), while porcelain insulators can be used for indoor applications (low cost and high stability).

English

English