I. Core Product Performance

1. Electrical Performance

High Breakdown Voltage: Power frequency breakdown strength ≥18 kV/mm (normal conditions). The breakdown strength is further improved after impregnation in transformer oil, effectively resisting electric field impacts during equipment operation and preventing insulation breakdown.

High Volume Resistivity: ≥10¹⁴ Ω·m (room temperature). Stable insulation resistance reduces the risk of leakage current and ensures the reliability of equipment insulation.

1. **Moderate Dielectric Constant:** Matches the dielectric constant of transformer oil (approximately 3.0~3.5), avoiding electric field distortion and reducing the probability of partial discharge.

2. **Physical and Mechanical Properties:**

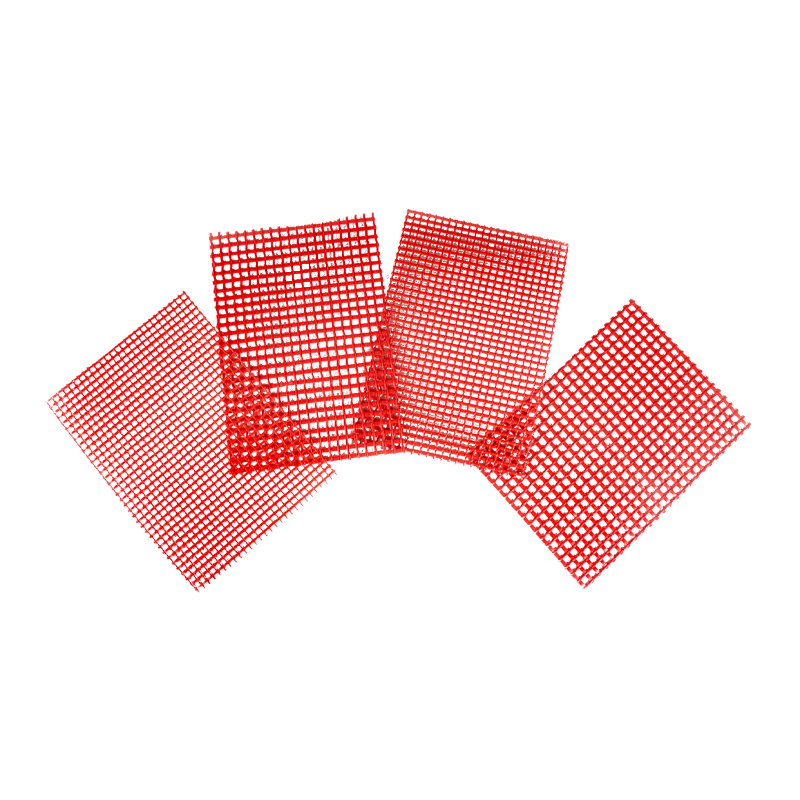

**Excellent Flexibility:** The wrinkled structure provides good tensile strength (longitudinal elongation at break ≥8%) and tear resistance, allowing for tight wrapping of windings, conductors, and other irregular components, adapting to equipment assembly process requirements.

**Uniform Basis Weight:** The standard basis weight range is 20~80 g/m², with a thickness deviation ≤±5%, ensuring uniform insulation layer thickness and avoiding localized weak points.

**High Oil Absorption:** The well-developed pore structure results in an oil absorption rate ≥200% (for transformer oil), enabling rapid and thorough impregnation to form an oil-paper composite insulation system, improving overall insulation performance.

3. **Chemical Stability:**

**Good Oil Resistance:** Excellent compatibility with mineral transformer oil and synthetic ester insulating oil; no swelling or degradation occurs during long-term immersion, and no harmful substances are produced.

Strong anti-aging ability: Contains antioxidant components (or undergoes modification treatment), resulting in a slow aging rate under the combined effects of high temperature (≤105℃) and electric field, with a service life ≥20 years (meeting transformer design life requirements).

Low ash content: Ash content ≤0.1%, reducing conductive impurities and avoiding partial discharge or insulation degradation caused by impurities.

4. Environmental adaptability

Heat resistance rating: Standard is Class A (heat resistance temperature 105℃), modified products can reach Class B (130℃), meeting the heat resistance requirements of transformers of different capacities.

Moisture resistance: Moisture content ≤6% under normal conditions, and performance can be restored after moisture absorption through drying, adapting to environmental humidity changes during transformer production, storage, and transportation.

II. Product Applications

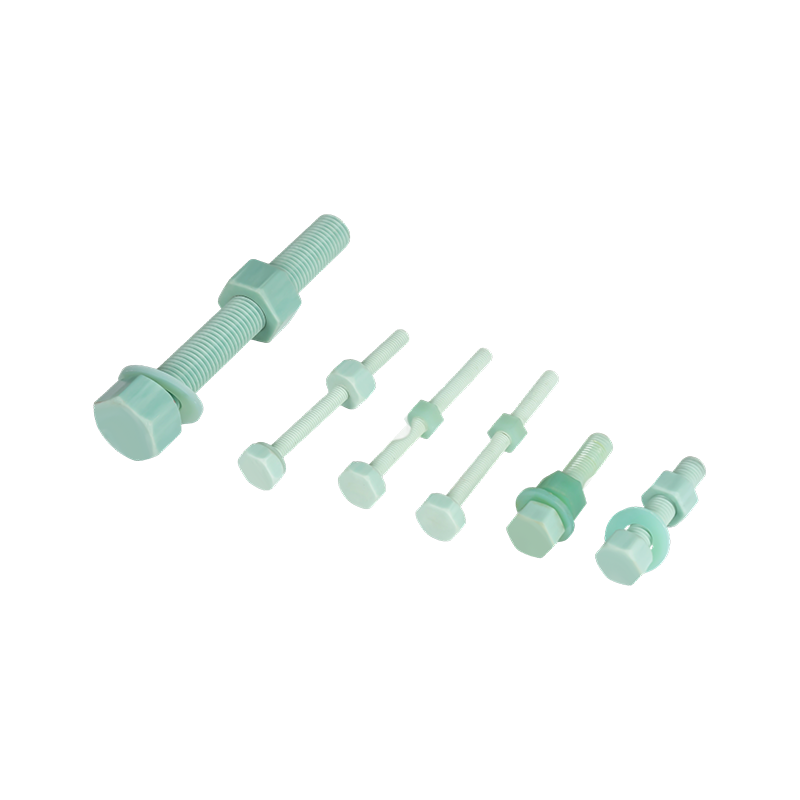

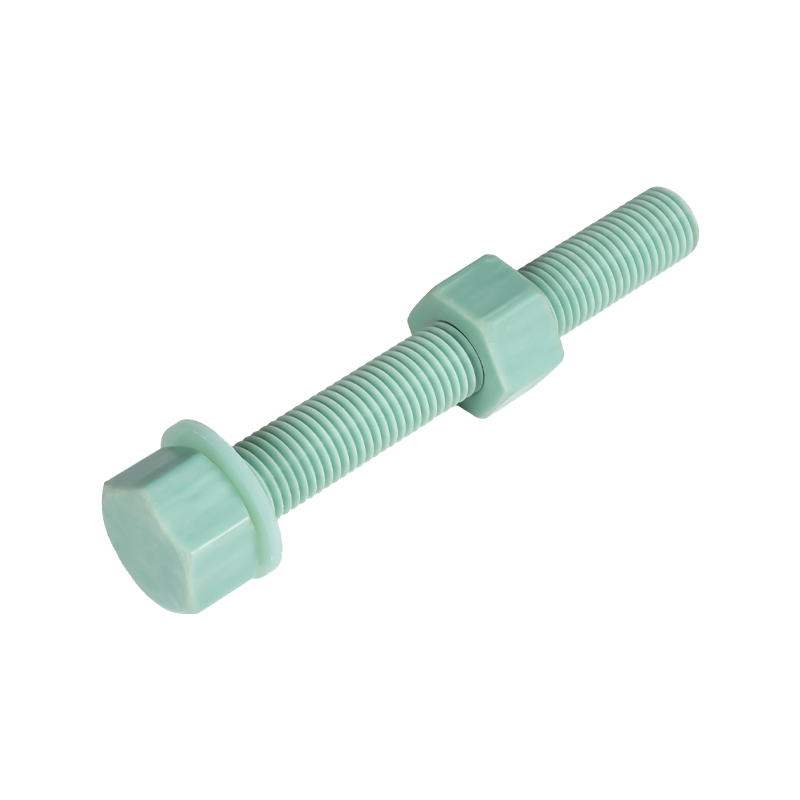

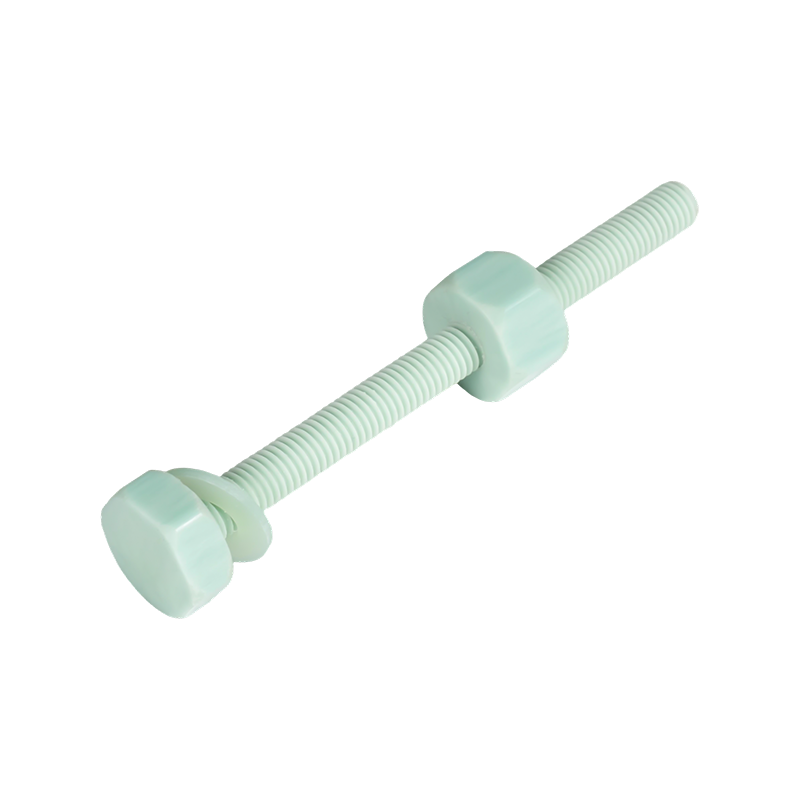

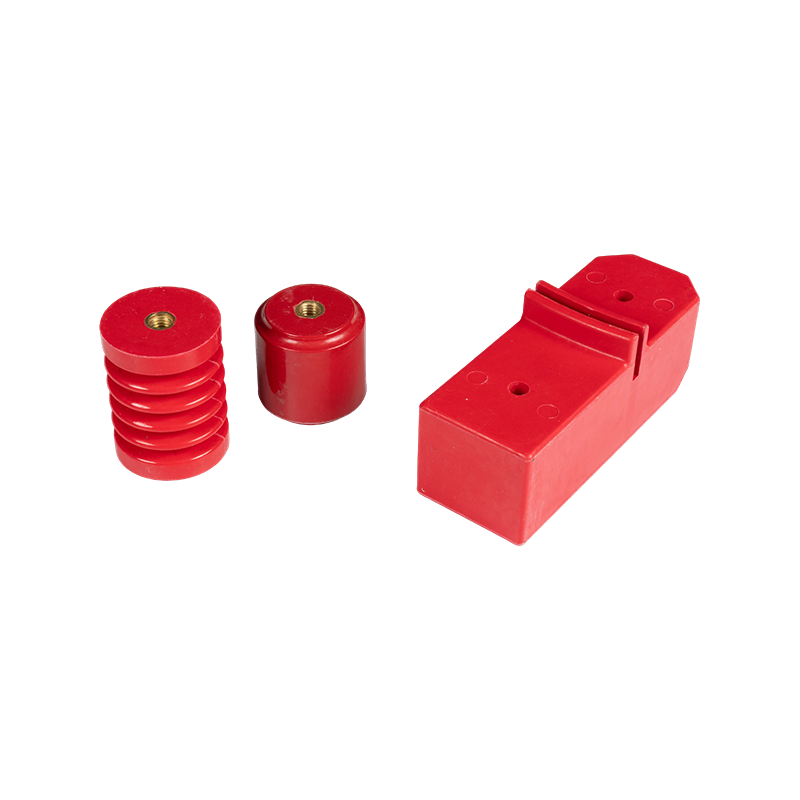

1. Transformer Internal Fastening

Core Clamping: Clamping bolts and nuts used for core laminations, replacing traditional steel bolts, avoiding eddy current losses caused by the core forming a conductive circuit with the bolts, reducing core temperature rise, suitable for core fixing in distribution and power transformers.

Winding Fixing: Serving as fastening screws and washers between winding pressure plates and clamps, isolating the winding (charged body) from the grounding clamps, preventing winding displacement or deformation, ensuring winding insulation distance, suitable for high-voltage, high-capacity transformers.

Insulation Component Assembly: Secures internal components such as tap changers, bushing flanges, and cooler connection seats, creating insulation between live parts and the grounding structure to prevent discharge caused by potential differences.

2. External Transformer Fastening

Shell and Accessory Fixing: Insulating bolts on the outer panel and guardrails of dry-type transformers isolate the shell from internal live parts to prevent electric shock; insulating fasteners for radiators and oil conservator supports of oil-immersed transformers, suitable for outdoor and coastal corrosive environments.

High-Voltage Bushing Fixing: Insulating bolts used for high-voltage bushings and transformer tank covers ensure insulation strength between the bushing and the tank, preventing leakage at bushing flanges. Suitable for transformers with voltage levels of 35 kV and above.

3. Special Transformer Applications

Dry-Type Transformers: Due to the lack of insulating oil impregnation, all internal fasteners must be made of fiberglass to prevent partial discharge caused by metal fasteners. Suitable for dry-type transformer applications in subways, buildings, mines, etc.

Corrosion/Explosion-proof Transformers: For transformers in corrosive/explosive environments such as chemical plants and oil fields, fiberglass fasteners are acid and alkali-resistant, flame-retardant, and explosion-proof, replacing easily corroded metal parts and extending equipment lifespan.

UHV Transformers: For the core insulation parts of 1000 kV UHV transformers (such as winding ends and tap changer areas), high-strength fiberglass fasteners are used, balancing insulation and mechanical stability to meet extreme operating conditions.

Supplementary Notes:

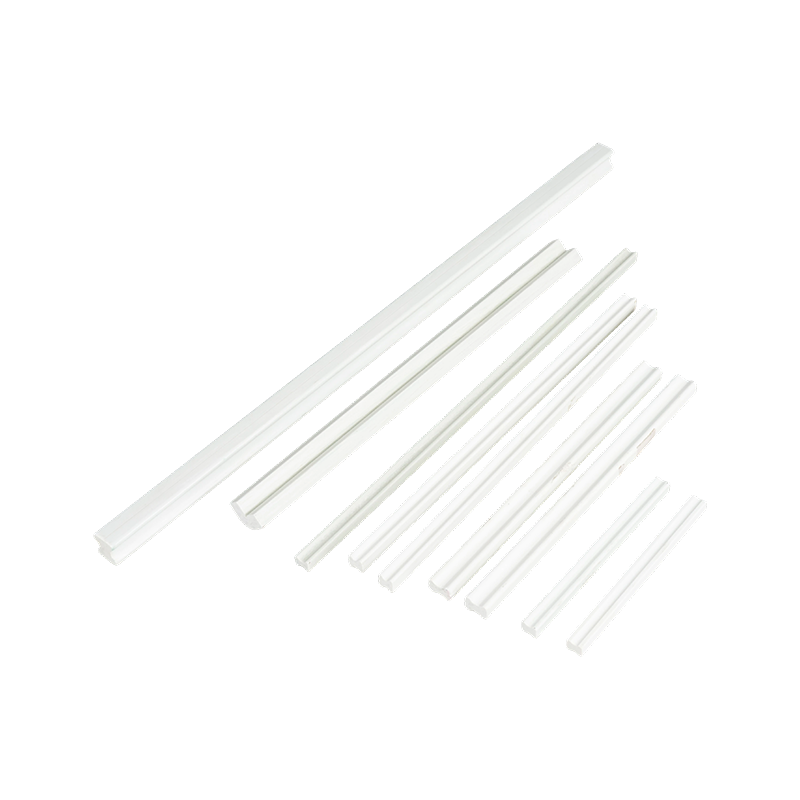

The model of fiberglass transformer fasteners must be selected according to the load, voltage level, and ambient temperature of the fastening part (e.g., molded parts are suitable for heavy-load parts, while pultruded parts are suitable for long screws); some products can be modified with antistatic and radiation-resistant components to suit transformers in special fields such as nuclear power and aerospace.

| No. | Item | Spec. | |||||

| M8 | M10 | M12 | M16 | M20 | M24 | ||

| 1 | Rod Shear Load - Single Nut | 4 | 7.2 | 12 | 16 | 19.2 | 25.6 |

| 2 | Rod Shear Load - Double Nut | 7.2 | 12.8 | 24 | 30.4 | 37.6 | 49.6 |

| 3 | Rod Bending Strength | 700 | 700 | 700 | 700 | 700 | 700 |

| 4 | Rod Tensile Strength (Longitudinal) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| 5 | Rod Tensile Modulus(Longitudinal) | 45 | 45 | 45 | 45 | 45 | 45 |

| 6 | Rod Shear Strength-double shear | 153 | 153 | 153 | 153 | 144 | 144 |

| 7 | Mounting Torque | 6 | 9 | 22 | 35 | 55 | 77 |

| 8 | AC Electric Strength | 5 | 5 | 5 | 5 | 5 | 5 |

| 9 | Relative Permittivity | 5 | 5 | 5 | 5 | 5 | 5 |

| 10 | Volume Resistivity | ≥ 10^10 | ≥ 10^10 | ≥ 10^10 | ≥ 10^10 | ≥ 10^10 | ≥ 10^10 |

| 11 | Coefficient of Thermal Expansion | 5-10×10^-6 | 5-10×10^-6 | 5-10×10^-6 | 5-10×10^-6 | 5-10×10^-6 | 5-10×10^-6 |

| 12 | Water Absorption | 1 | 1 | 1 | 1 | 1 | 1 |

| 13 | Density | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 |

English

English