II. Performance Characteristics

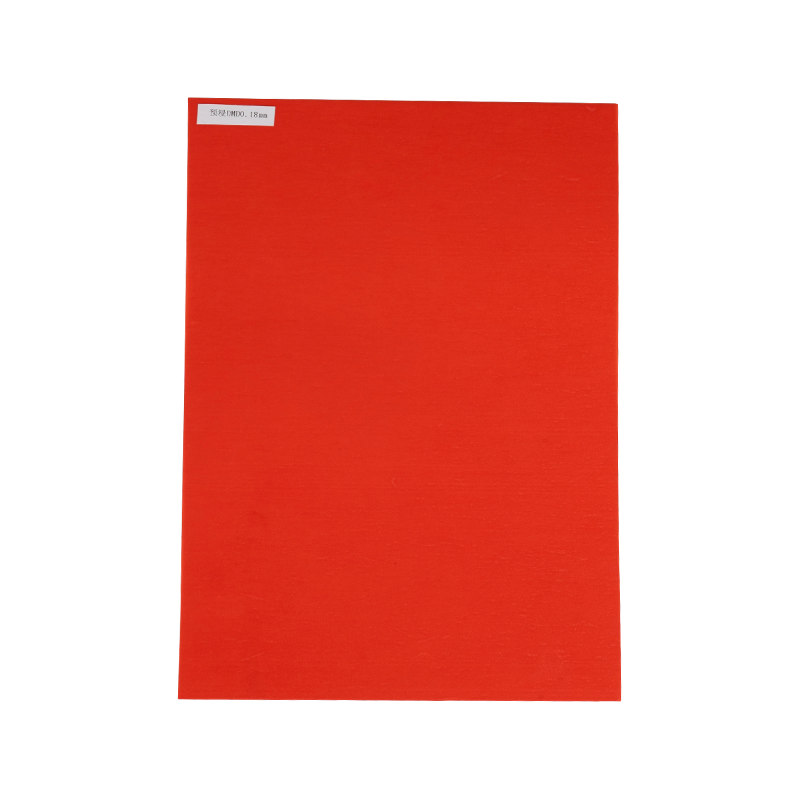

1. Excellent Heat Resistance: Possesses reliable heat resistance, mostly F-grade heat resistance, with a long-term operating temperature up to 155℃. It can adapt to the temperature rise environment during dry-type transformer operation and is not prone to aging or deformation.

2. Strong insulation and withstand voltage: High dielectric strength, with a breakdown voltage exceeding 30kV in the unbent state, providing excellent high-voltage resistance and effectively isolating coil potential differences to prevent insulation failures such as short circuits.

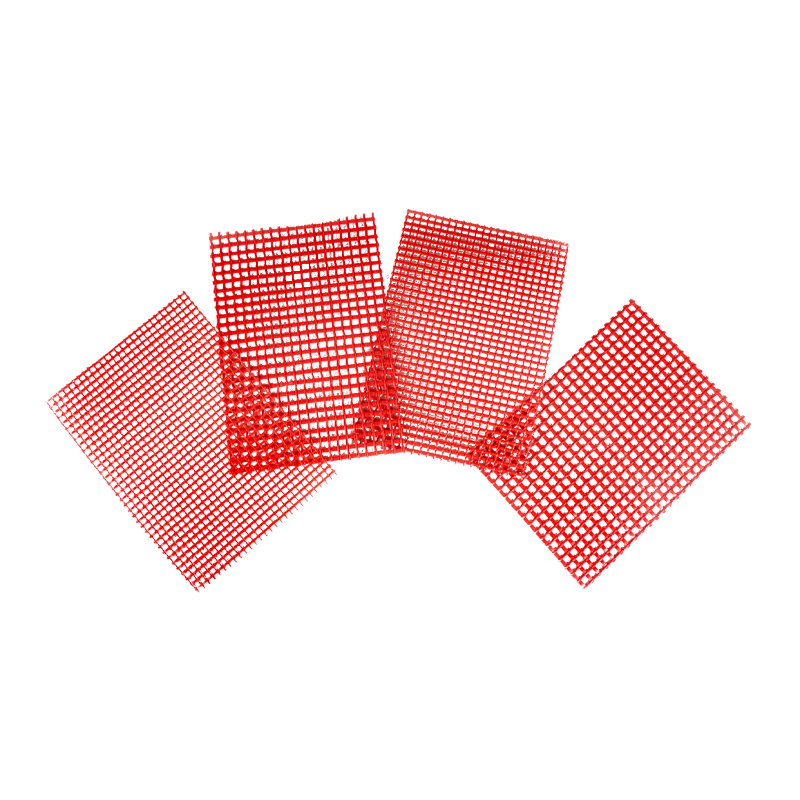

3. Stable mechanical properties: High tensile strength, ≥350N/10mm in both longitudinal and transverse directions when unbent; strong tear resistance, able to withstand tensile forces and electrodynamic impacts during coil winding and installation, suitable for automated winding processes.

4. Good environmental adaptability: Extremely low shrinkage and moisture absorption, maintaining stable performance even in complex environments such as high humidity, reducing the probability of insulation failures caused by moisture, eliminating the need for additional moisture-proofing treatment.

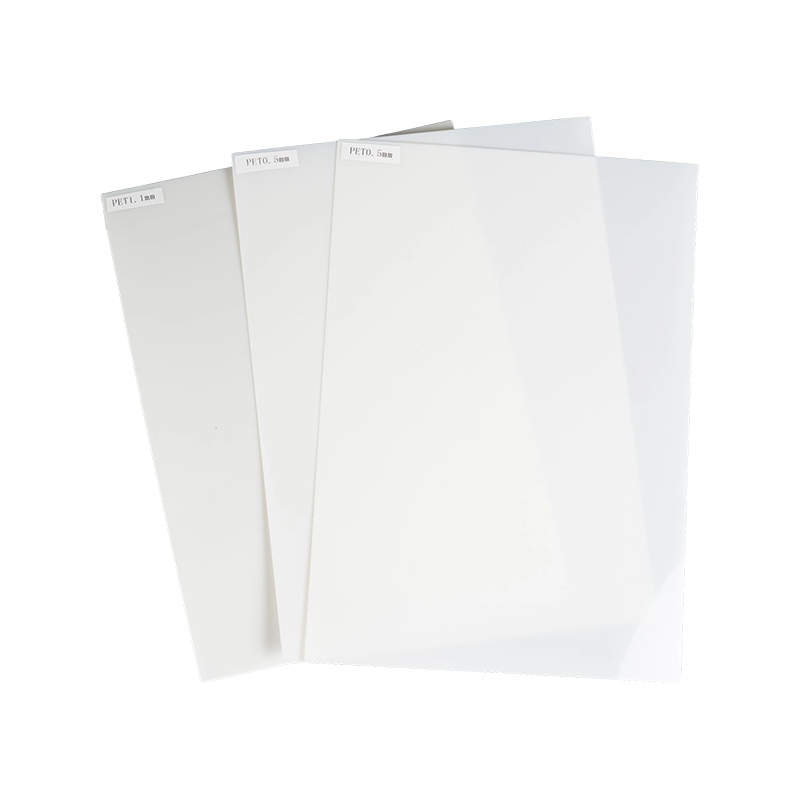

5. Excellent composite properties: Formed using a high-voltage pressing process, the multi-layered structure is tightly bonded, with no delamination, resulting in a long service life and ensuring long-term stable transformer operation.

III. Core Applications

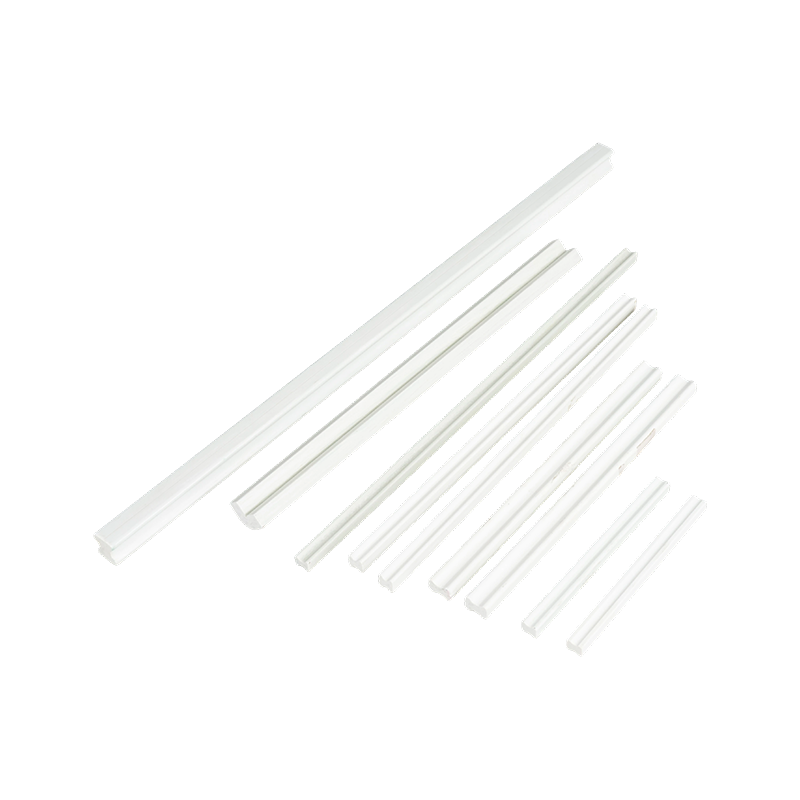

1. Coil Inner Mold and Insulating Cylinder: Primarily used for winding inner molds of low-voltage coils in dry-type transformers. It can directly replace epoxy resin boards and phenolic resin boards in the production of insulating cylinders, reducing mold investment and improving production efficiency.

2. Coil-to-Coil and End-Sealing Insulation: Suitable for insulation isolation between high- and low-voltage coils in dry-type transformers. It can also be used as coil end-sealing insulation and padding insulation, filling coil gaps, dispersing electric field stress, and suppressing partial discharge.

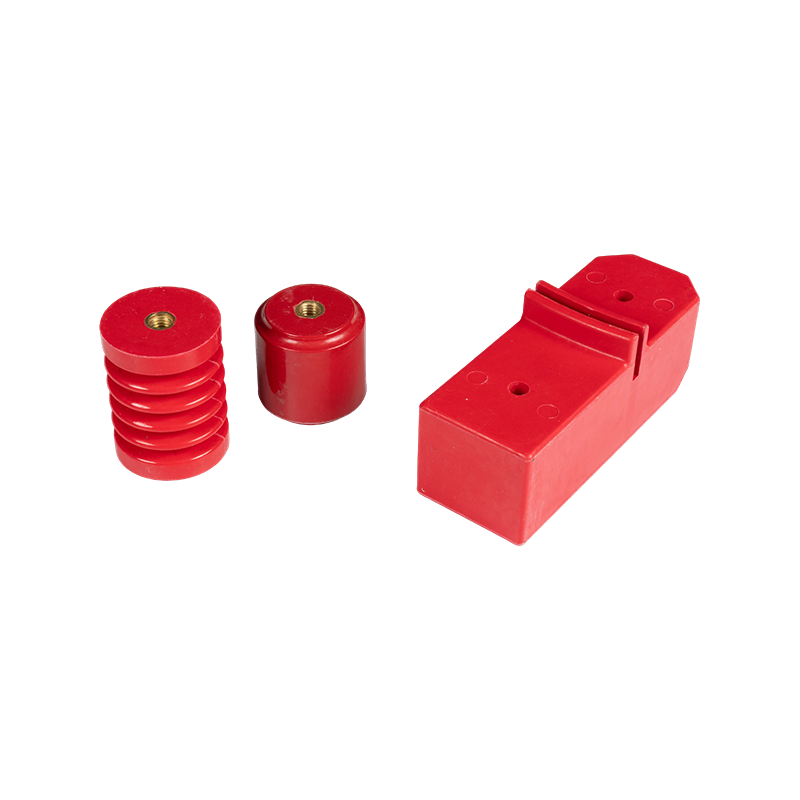

. Terminal and Lead Wire Auxiliary Insulation: Can be used to wrap high-voltage terminals of transformers, isolating them from air, preventing terminal aging and corrosion, and protecting terminal safety. It can also be used to assist in the insulation filling of lead wire joints, strengthening insulation protection in complex structures.

English

English