I. Core Product Performance

1. Electrical Performance

High Breakdown Voltage: Power frequency breakdown strength ≥18 kV/mm (normal conditions). The breakdown strength is further improved after impregnation in transformer oil, effectively resisting electric field impacts during equipment operation and preventing insulation breakdown.

High Volume Resistivity: ≥10¹⁴ Ω·m (room temperature). Stable insulation resistance reduces the risk of leakage current and ensures the reliability of equipment insulation.

1. **Moderate Dielectric Constant:** Matches the dielectric constant of transformer oil (approximately 3.0~3.5), avoiding electric field distortion and reducing the probability of partial discharge.

2. **Physical and Mechanical Properties:**

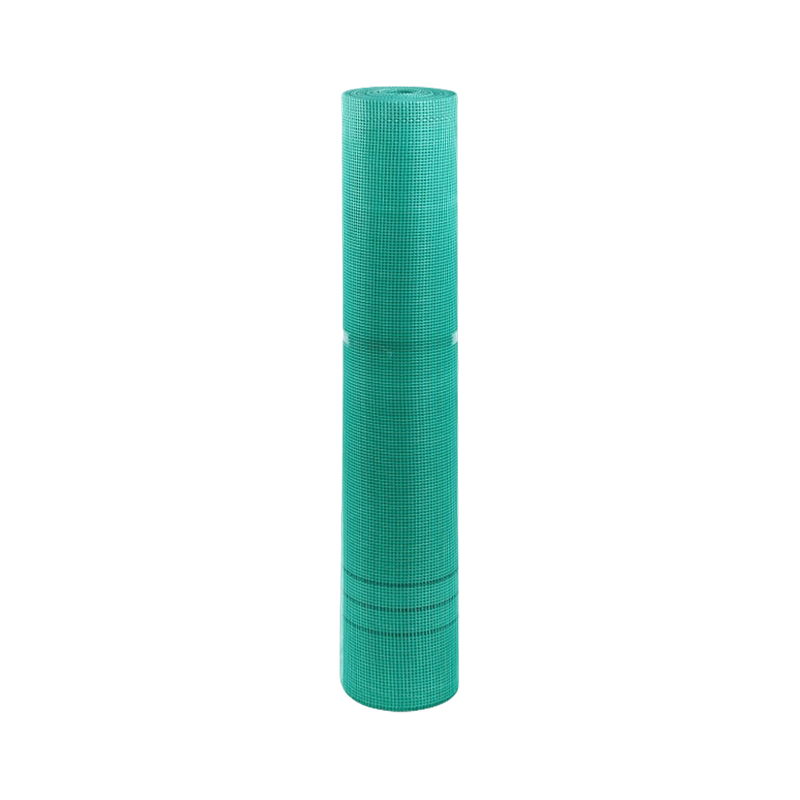

**Excellent Flexibility:** The wrinkled structure provides good tensile strength (longitudinal elongation at break ≥8%) and tear resistance, allowing for tight wrapping of windings, conductors, and other irregular components, adapting to equipment assembly process requirements.

**Uniform Basis Weight:** The standard basis weight range is 20~80 g/m², with a thickness deviation ≤±5%, ensuring uniform insulation layer thickness and avoiding localized weak points.

**High Oil Absorption:** The well-developed pore structure results in an oil absorption rate ≥200% (for transformer oil), enabling rapid and thorough impregnation to form an oil-paper composite insulation system, improving overall insulation performance.

3. **Chemical Stability:**

**Good Oil Resistance:** Excellent compatibility with mineral transformer oil and synthetic ester insulating oil; no swelling or degradation occurs during long-term immersion, and no harmful substances are produced.

Strong anti-aging ability: Contains antioxidant components (or undergoes modification treatment), resulting in a slow aging rate under the combined effects of high temperature (≤105℃) and electric field, with a service life ≥20 years (meeting transformer design life requirements).

Low ash content: Ash content ≤0.1%, reducing conductive impurities and avoiding partial discharge or insulation degradation caused by impurities.

4. Environmental adaptability

Heat resistance rating: Standard is Class A (heat resistance temperature 105℃), modified products can reach Class B (130℃), meeting the heat resistance requirements of transformers of different capacities.

Moisture resistance: Moisture content ≤6% under normal conditions, and performance can be restored after moisture absorption through drying, adapting to environmental humidity changes during transformer production, storage, and transportation.

II. Product Applications

1. Winding insulation

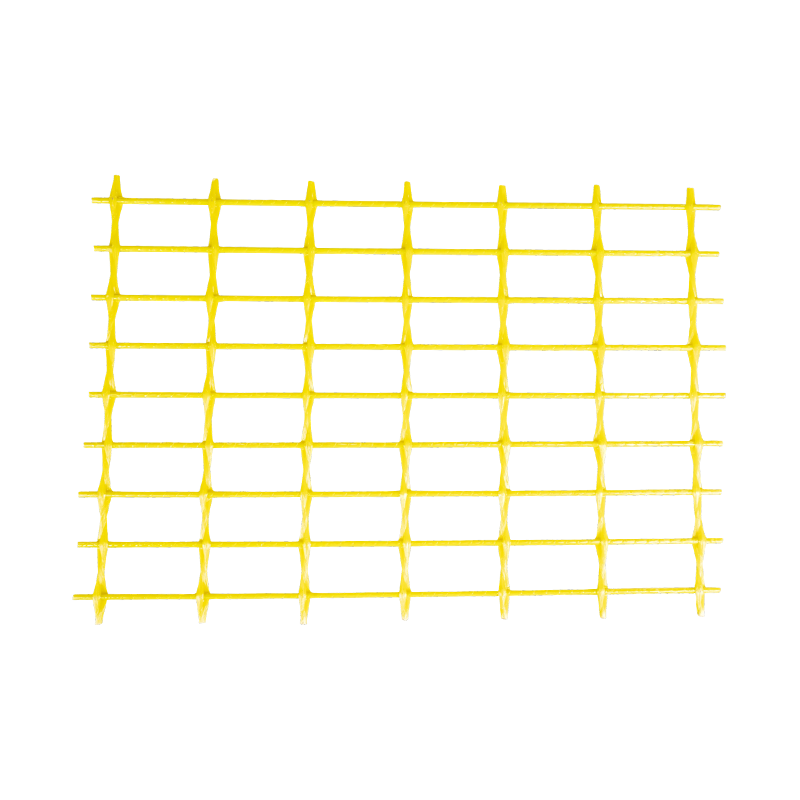

Inter-turn insulation: Wound between transformer winding turns to isolate adjacent turns and prevent inter-turn short circuits, suitable for low-voltage, medium-voltage, and high-voltage windings. - Interlayer Insulation: Pads placed between winding layers as the main interlayer insulation, bearing the interlayer voltage. Commonly found in the winding structures of distribution transformers and power transformers.

End Insulation: Insulating pads are used at the winding ends to protect them from concentrated electric fields. Used in conjunction with end rings and pressure plates.

2. Lead and Joint Insulation

Lead Wrapping: Wraps the high and low voltage leads of the transformer, tap changer leads, and isolates the leads from the core, tank, and other grounding components to prevent flashover.

Joint Insulation: Used for insulating winding outlet joints and bushing terminals to enhance insulation strength at the joints, meeting the requirements of high-voltage equipment (such as 110 kV and above transformers).

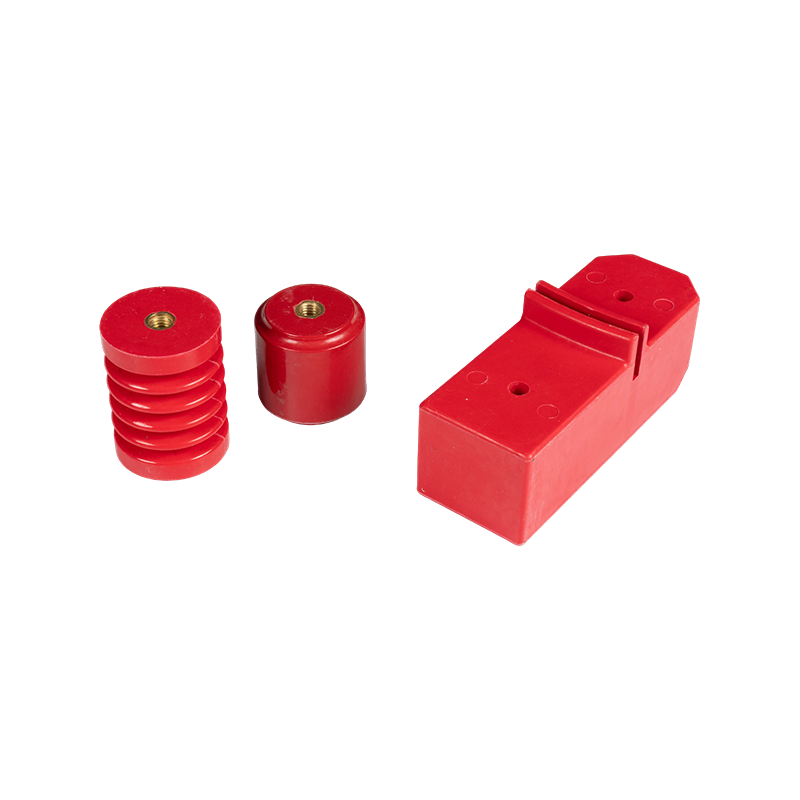

3. Structural Insulation

Support Bar/Pack Insulation: Used in conjunction with insulating cardboard to create internal support bars and pads for the transformer. Used to fix the windings and core, while also providing insulation to ensure electrical isolation between structural components.

Separator insulation: As an insulating separator inside the oil tank and between the winding and the core, it separates different potential areas, optimizes the electric field distribution, and is suitable for large-capacity, high-voltage transformers.

English

English