Features:

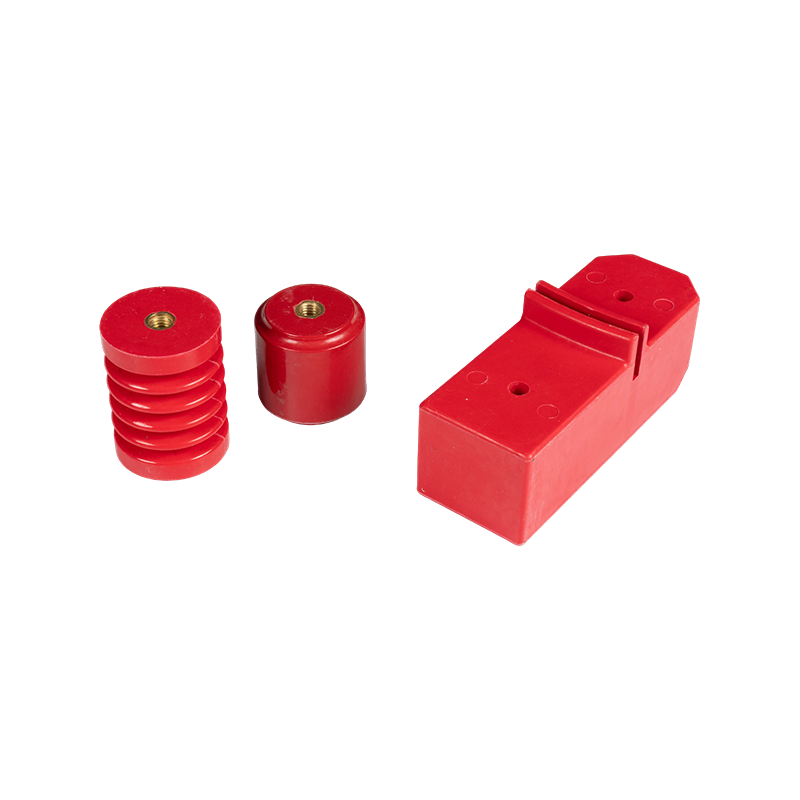

Insulation: High insulation resistance and breakdown voltage, suitable for high-voltage electrical equipment.

Mechanical Strength: High tensile strength, effectively dispersing and bearing stress.

Temperature Resistance: H-class temperature resistance, capable of long-term operation at 180℃.

Chemical Resistance: The epoxy resin layer provides excellent resistance to acid, alkali, and solvent corrosion.

Dimensional Stability: Low water absorption (typically ≤1.17%), minimal deformation under varying humidity conditions.

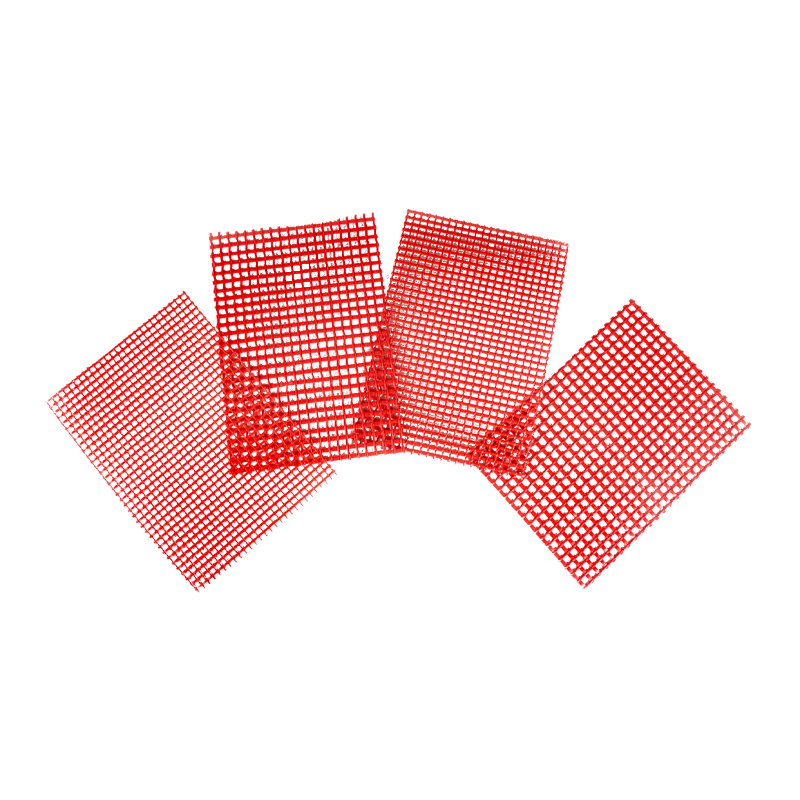

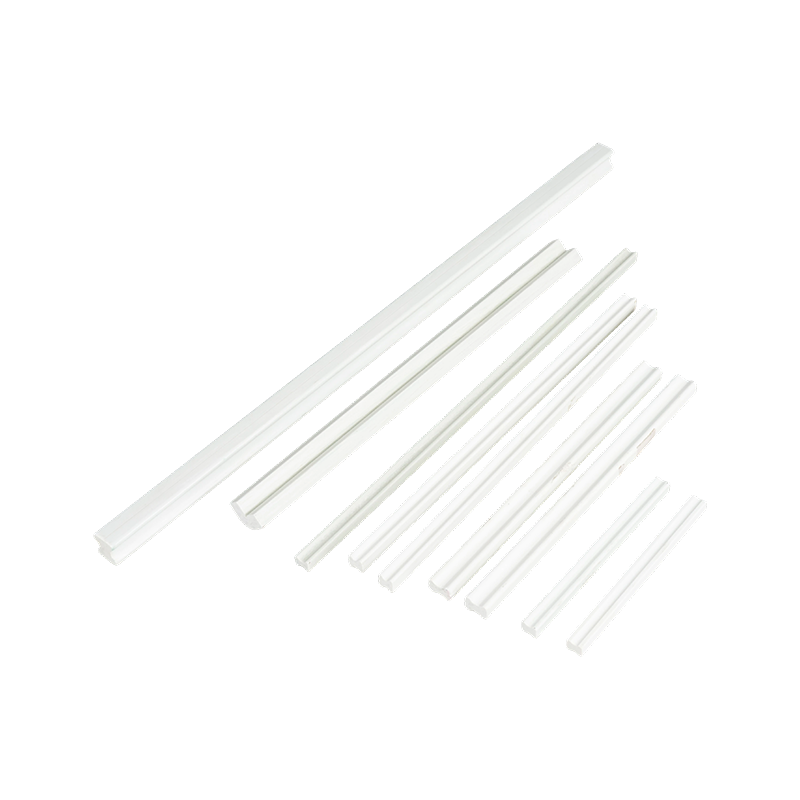

Multiple Specifications: Available in various thicknesses (e.g., 0.4mm to 2.4mm), mesh sizes, and weight per unit area.

Main Applications:

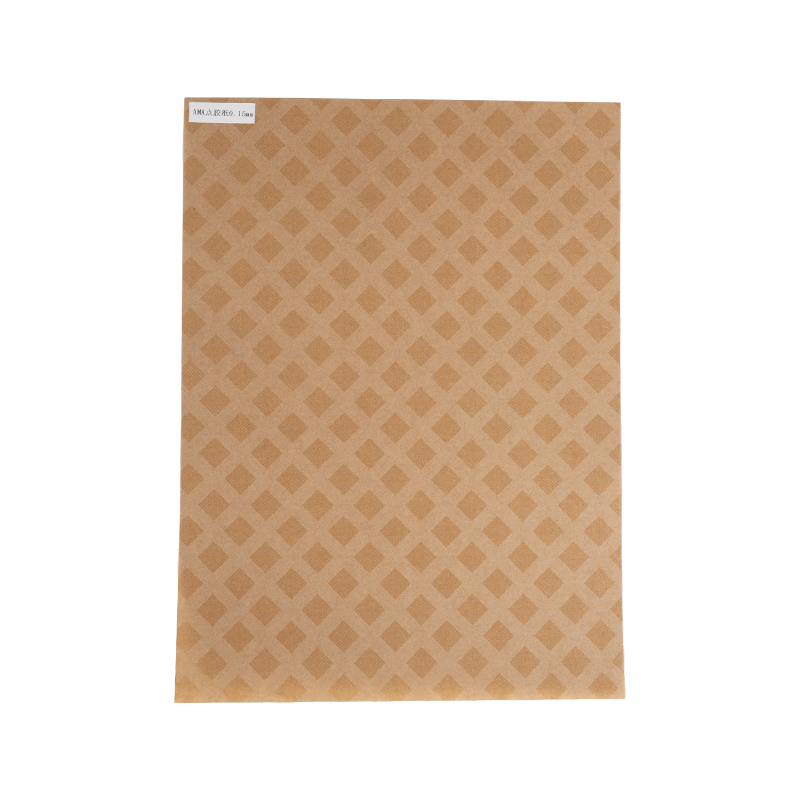

Power and Electrical Industry: Widely used in the casting of coils for cast-in-place dry-type transformers and reactors. In this application, the epoxy fiberglass mesh is firmly bonded to the epoxy resin, forming a reinforced skeleton similar to reinforced concrete. This effectively prevents cracking of the outer insulation layer caused by thermal effects or the enormous electrodynamic forces during sudden short circuits, significantly improving the overall mechanical strength and insulation life of the coil.

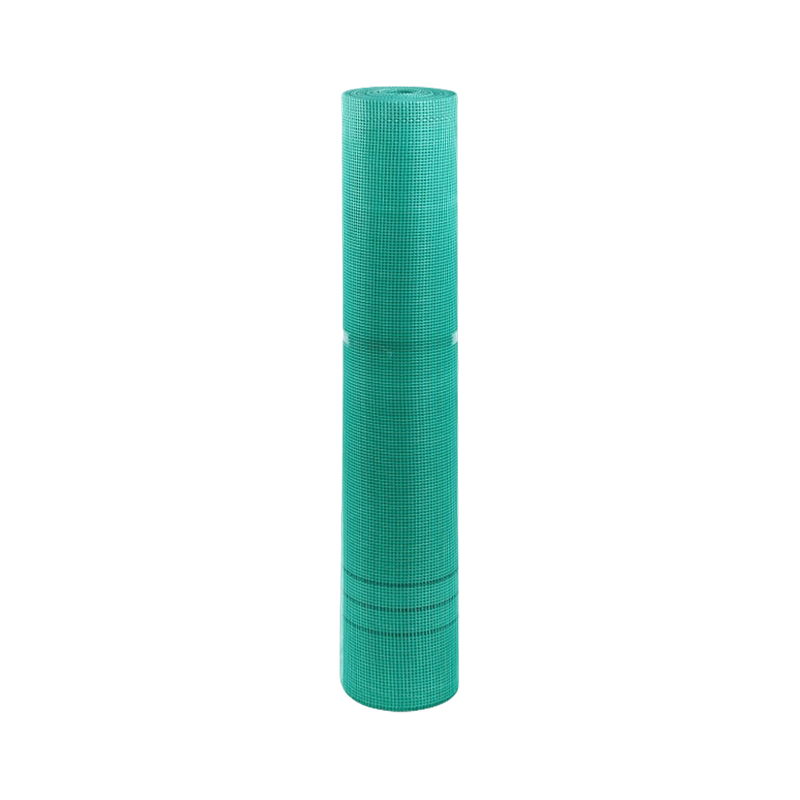

In the construction industry: It is used to reinforce cement products, wall insulation systems, roof waterproofing, and as a backing reinforcement for materials such as marble and mosaic. Its excellent alkali resistance and high tensile strength effectively prevent cracking caused by overall surface tension shrinkage of the plaster layer and external forces.

Industrial protection and others: It is also used in industrial environments requiring corrosion resistance and high temperature resistance (such as pipeline and tank protection) and in certain electronic and electrical components (such as circuit boards).

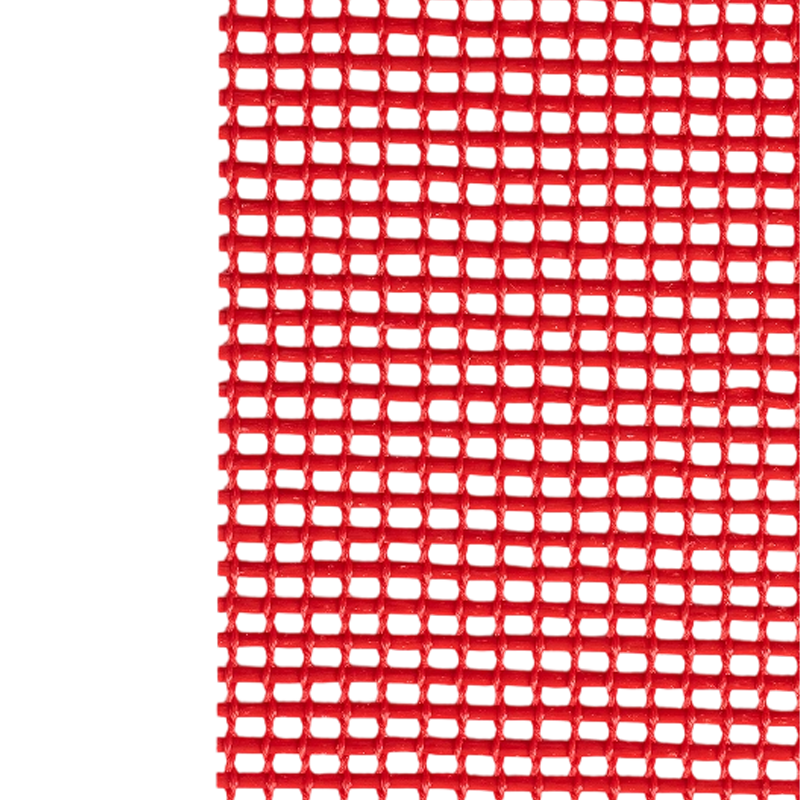

| Serial number | Mesh size (longitude*latitude) | Thickness (mm) | Square gram weight (g/m²) | Conventional roll length (m) | Width (m) | Glue content (%) | Tensile strength (N) |

| 1 | 4*5mm | 0.5±10% | 180±10% | 100±0.5 | 0.2–1.4 | 12–18 | 800 |

| 2 | 4*5mm | 0.6±10% | 220±10% | 100±0.5 | 0.2–1.4 | 12–18 | 1000 |

| 3 | 4*5mm | 1.2±10% | 620±10% | 50±0.5 | 0.2–1.4 | 12–18 | 2400 |

| 4 | 5*6mm | 1.6±10% | 880±10% | 50±0.5 | 0.2–1.4 | 12–18 | 3400 |

| 5 | 5*6mm | 2.0±10% | 1100±10% | 40±0.5 | 0.2–1.4 | 12–18 | 4200 |

English

English