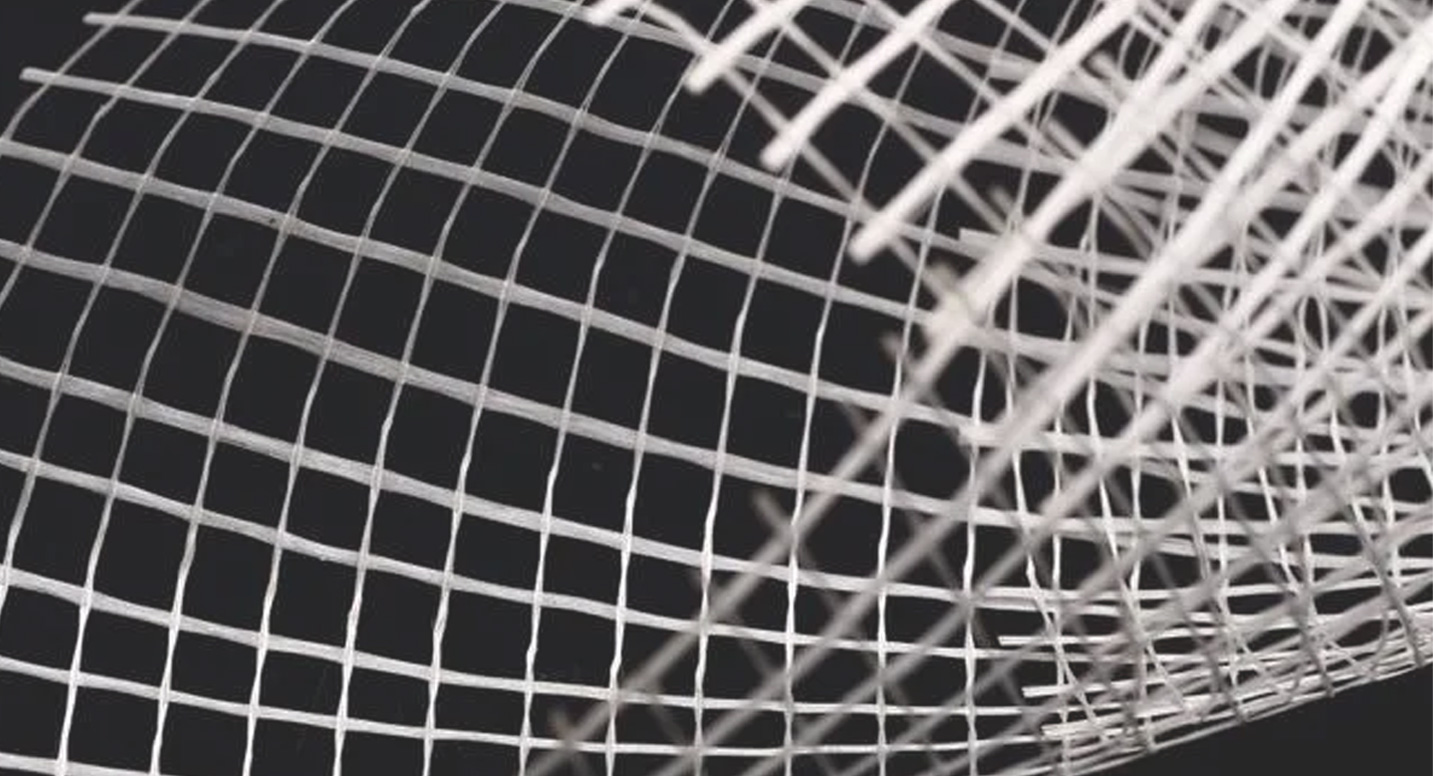

In the modern industrial field where the performance limits and reliability of materials are pursued, the selection of reinforcing materials directly determines the final performance of composite material products. Today, we are proud to present its core product - high-performance epoxy glass grid cloth. This product, with its outstanding mechanical properties, excellent chemical stability and outstanding process adaptability, is becoming an indispensable key reinforcing material in high-end composite material fields such as wind turbine blades, shipbuilding, rail transit, building reinforcement and sports equipment, providing a solid guarantee for structural safety and long-lasting durability in various harsh application environments.

Core advantage: Three-dimensional integration, defining a new standard for reinforcing materials

Epoxy glass mesh fabric is not merely a glass fiber fabric, but a professional reinforcing base material treated with special sizing agents and optimized weaving processes. Its core value is reflected in three dimensions:

Outstanding mechanical reinforcement performance

High strength and high modulus: Made from high-quality alkali-free glass fiber yarns, it is precisely woven to form a uniform and stable grid structure, which can effectively disperse and transfer loads, providing extremely high tensile strength and rigidity for composite material products. It is an ideal "skeleton" for withstanding heavy loads and resisting deformation.

Excellent impact resistance and fatigue resistance: The grid structure has a good strain distribution capacity, which can absorb and disperse impact energy, significantly enhancing the impact toughness of the product. Meanwhile, its excellent interfacial bonding force with the epoxy resin matrix ensures the fatigue resistance of the composite material under long-term dynamic loads.

Outstanding environmental adaptability and durability

Outstanding corrosion resistance: It has extremely strong resistance to most acids, alkalis, salts and other chemical media, does not rust or corrode, and is especially suitable for corrosive environments such as Marine environments (ships, offshore platforms), chemical storage tanks, and sewage treatment facilities.

Excellent dimensional stability: The coefficient of thermal expansion is well matched with that of epoxy resin, and it is less likely to generate internal stress during the curing process and temperature changes, ensuring precise dimensions and stable shapes of the products, and preventing warping and deformation.

Excellent electrical insulation performance: It has good electrical insulation characteristics and is suitable for reinforcing electrical equipment components, insulation boards and other fields.

Excellent process adaptability

Perfect match with epoxy resin: The dedicated sizing agent ensures excellent wettability and adhesion to the epoxy resin system. The resin is easy to penetrate, and the interface is firmly bonded after curing, without white threads or delamination.

Good covering property and operability: The fabric is soft and flexible, and can well fit the complex mold shapes. It is suitable for various forming processes such as hand lay-up, vacuum introduction, and compression molding. The construction is convenient and efficient.

Wide application: Empowering thousands of industries and building a safe future

The application of epoxy glass mesh fabric is playing a key role in multiple fields that are crucial to the national economy and people's livelihood as well as the cutting-edge of science and technology

In the field of new energy wind power: As the core reinforcing material for the main beam, shell and key parts of wind turbine blades, its high strength and light weight characteristics directly affect the wind capture efficiency, structural safety and service life of the blades, and are the foundation for promoting the development of large-scale and lightweight wind turbine blades.

In the field of transportation: It is used in high-speed train bodies, subway components, bus bodies, special vehicles, as well as ship hulls and decks. It can significantly reduce weight, enhance strength, and improve corrosion resistance, contributing to energy conservation, emission reduction, and safe operation.

Construction engineering and reinforcement: In the reinforcement and repair of concrete structures, epoxy glass mesh fabric is used in combination with epoxy structural adhesives to form a high-performance composite material reinforcement layer, which can significantly enhance the load-bearing capacity, seismic resistance and aging resistance of the structure. The construction is fast and does not affect the appearance of the original structure.

Sports, leisure and industrial equipment: It is used to manufacture high-performance racing boats, windsurfing boards, poles, safety helmets, amusement equipment, as well as various corrosion-resistant storage tanks, pipes, environmental protection equipment, etc., meeting the ultimate pursuit of lightness, high strength and durability.

Industry leadership and continuous innovation

The successful research and development and large-scale application of epoxy glass mesh fabric reflect the profound technical accumulation in the field of advanced reinforcing materials and the precise grasp of market demands. The company adheres to a strict quality control system, from raw material selection to weaving treatment, to ensure the stable and reliable performance of each roll of products.

The reinforcing materials we understand are not only physical reinforcement but also an empowerment of the value and safety commitment of our customers' products. Our epoxy glass mesh fabric is designed to provide the most reliable solutions for the most demanding application scenarios.

Facing the trend of the composite materials industry towards high performance, multi-functionality and green development, we will continue to invest in research and development, optimize the product series, and develop more targeted epoxy glass mesh fabric products (such as higher modulus, thinner weight, special coatings, etc.). We will join hands with partners in the industrial chain to jointly promote the innovative development of downstream application fields. Contribute to building a safer, more efficient and more sustainable industrial future.

Regarding epoxy glass mesh fabric

Epoxy glass mesh fabric is a reinforced fabric made from alkali-free glass fiber yarn as raw material, treated with special weaving methods and sizing agents, and specially designed for use in conjunction with epoxy resin systems. It has a regular grid structure, and its main function is to be embedded in composite materials, providing the main mechanical load-bearing capacity and improving the impact resistance, fatigue resistance and dimensional stability of the composite materials. It is the core skeleton material of high-performance composite material products.