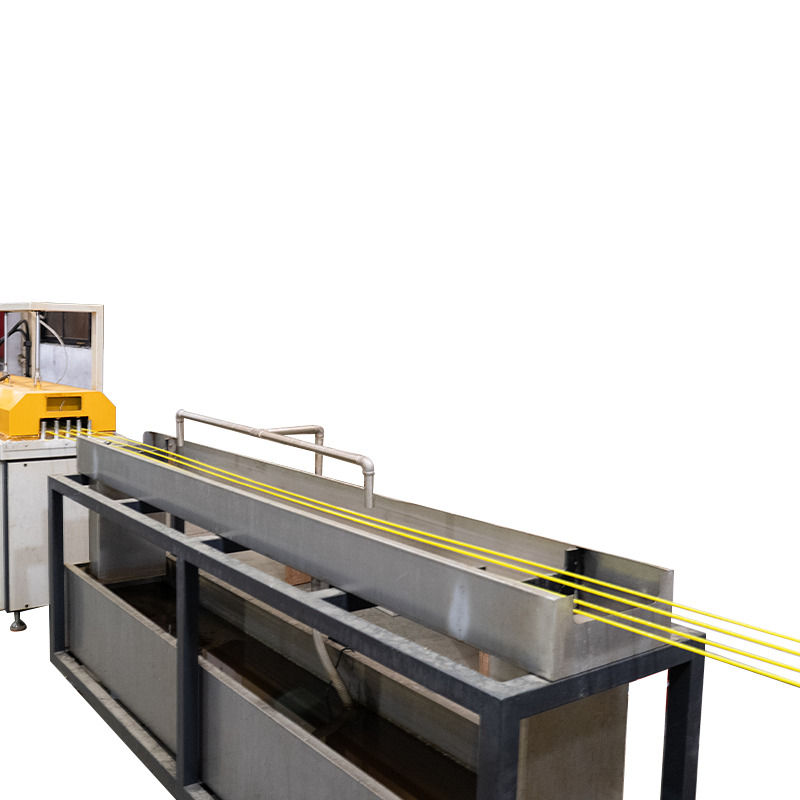

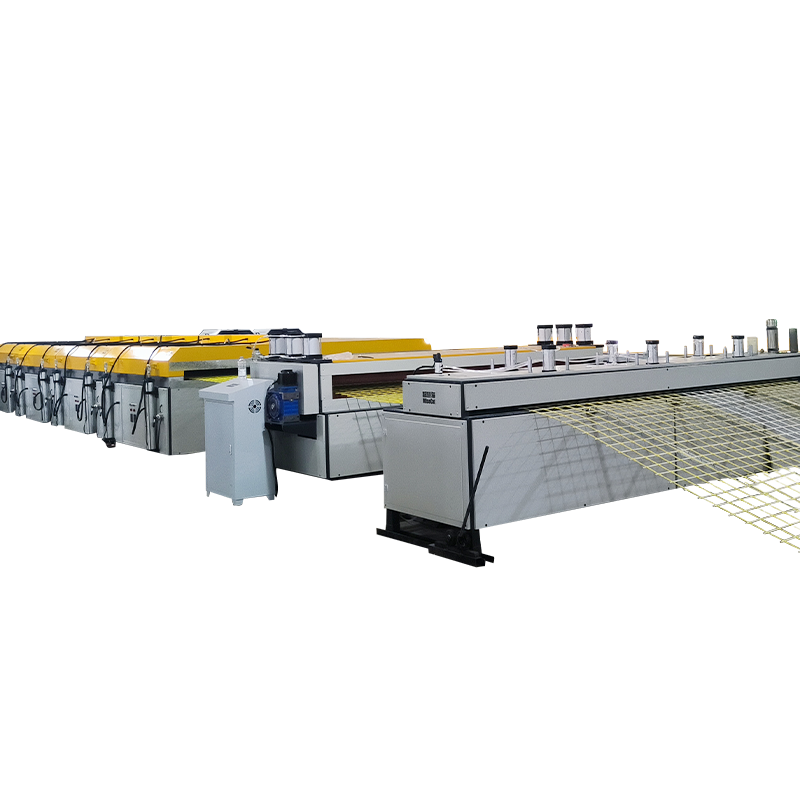

Four-Strand GFRP Rebar Pultrusion Line

The Four-Strand GFRP Rebar Pultrusion Line is a specialized equipment system for the continuous production of high-performance four-filament glass fiber reinforced polymer (GFRP) rebars. Compared to traditional monofilament or twin-filament pultrusion lines, the core difference and advantage of this system lies in its ability to integrate four independent glass fiber bundles for impregnation and molding in a single operation. This design significantly improves production efficiency and the uniformity of the product's mechanical properties. Through precise tension control and a resin impregnation system, the Four-Strand GFRP Rebar Pultrusion Line ensures that the four fiber bundles are fully and uniformly encapsulated within the polymer matrix, resulting in GFRP rebars with higher tensile strength, superior adhesion, and more stable dimensional accuracy. This production line is particularly suitable for large-scale infrastructure construction material supply applications where high capacity and product consistency are critical.

English

English